Main page

About us

Sliding Bearings Consulting

Advertising Opportunities

SubsTech’s sister website Smooth Sliding provides independent engineering consulting services that help you to solve engine bearing related issues: failures, material selection, geometry design and optimization of hydrodynamic conditions.

Smooth Sliding is an engineering consulting company run by Dr. Dmitri Kopeliovich:

- VP R&D of King Engine Bearings.

- World leading expert (32 years of experience) in design, technology and materials for Engine bearings in applications such as automotive, renewable energy, aviation, racing and others.

- Founder and owner of SubsTech (Substances & Technologies) – a leading professional website on Materials Science and Engineering.

- Author of numerous scientific and engineering publications and patents.

- Founder and owner of Smooth Sliding.

For further information and for requesting consulting services please visit our sister website Smooth Sliding.

to Metals

to Engine bearings

Aluminum based bearing materials

Dr. Dmitri Kopeliovich

Aluminum based Engine bearing materials provide a good combination of a moderate fatigue strength (load capacity) with a moderate level of anti-friction properties (compatibility, conformability, embedability).

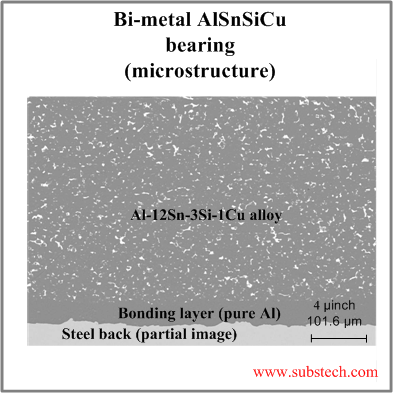

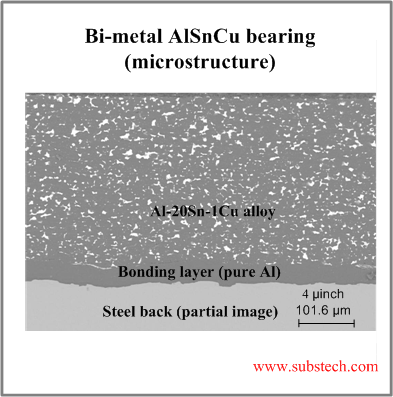

Most aluminum based bearing materials have bi-metal structure. The manufacturing technology of aluminum based bearing materials includes continuous casting followed by bonding the alloy with a steel strip.

Aluminum base bearing materials are:

- Less expensive than Copper based bearing materials;

- Contain no (or low) hazardous lead;

- Possess good corrosion resistance, low wear rate;

- Do not require (in most cases) overlays.

Composition of aluminum based bearing alloys

- Tin (Sn). Aluminum based bearing alloys commonly contain tin (6-40%) as a soft component. Tin is distributed in aluminum matrix as a separate phase in form of a reticular (network) structure along the edges of aluminum grains.

Tin imparts to the material anti-friction properties (compatibility, conformability, embedability).

- Silicon (Si). Some of aluminum based bearing alloys contain silicon. Silicon has very high hardness and its inclusions distributed over the aluminum matrix serve as an abrasive particles polishing the mating journal surface.

The abrasive effect of aluminum based bearing alloys containing silicon is particularly important for the crankshafts made of nodular (ductile) cast irons consisting of spheroid nodular Graphite particles within the ferrite matrix. Grinding of the shaft surface causes formation of burred caps of ferrite surrounding the graphite nodules. These sharp edges scratch the bearing surface and decrease its seizure resistance. During the engine operation microscopic silicon particles included in the aluminum matrix remove the ragged edges from the shaft surface. Silicon also hardens the aluminum alloy and increases its fatigue strength.

- Strengthening elements. Aluminum matrix of engine bearing alloys may be strengthened by addition of copper, nickel, chromium, manganese, magnesium, zinc.

Most aluminum based alloys are solid solution hardened – strengthening by dissolving an alloying element. However some of the alloys may be dispersion hardened (heat treatable alloys) – strengthening by addition of second phase into metal matrix (Al2Cu, Mg2Si).

Aluminum based bearing alloys are manufactured by continuous casting technology.

In contrast to the copper based bearing alloys, anti-friction properties of which are poor aluminum based tin containing alloys may be used without soft anti-friction overlays.

Most aluminum based engine bearings have bi-metal structure consisting of two layers: a steel back and an aluminum-tin alloy of about 0.01” (0.25 mm) thick.

Load carrying capacity of bi-metal Al20Sn1Cu bearing is 5800 psi (40 MPa).

Load carrying capacity of bi-metal aluminum-tin-silicon-copper bearing is 7250-8700psi (50-60 MPa).

The bearing materials not containing tin or containing low content of tin (less than 6%) are overplated with a thin soft overlay (tri-metal structure and multi-layer structures). The overlay parameters are similar to those used for tri-metal copper based bearings.

Load carrying capacity of tri-metal (overplated) aluminum based bearings is determined by the fatigue strength of the overlays:

- Lead based overlays: 7250-10150psi (50-70 MPa)

- Sputter overlays: 14500-17400 psi (100-120 MPa)

Characteristics of some aluminum based engine bearing materials

| Composition | Structure | Hardness, HV | Overlay | Applications |

|---|---|---|---|---|

| Al20Sn1Cu | Bi-metal | 35 | no | Low loaded bearings |

| Al40Sn1Cu | Bi-metal | 30 | no | Low loaded bearings, excellent seizure resistance |

| Al8Sn2Pb2.5Si0.8Cu0.2Cr | Bi-metal, no bonding layer | 40 | no | Low and medium loaded bearings, good seizure resistance |

| Al12Sn4Si1Cu | Bi-metal | 45 | no | Low and medium loaded bearings, good seizure resistance, lead free |

| Al4Si0.5Cu0.5Mg | Tri-metal | 70 (precipitation hardened) | Pb10Sn3Cu | Low and medium loaded bearings, good seizure resistance, lead free |

| Al6.5Sn1Cu0.5Ni | Tri-metal | 40 | Pb18Sn2Cu with nickel barrier | Highly loaded bearings |

| Al6.5Sn1Cu0.5Ni | Tri-metal | 40 | MoS2 in resin | Racing car engine bearings |

| Al6.5Sn1Cu0.5Ni | Solid | 40 | no | Thrust washers |

| Al11Si11Mg1Cu1Ni | Solid | 100 (precipitation hardened) | Pb18Sn2Cu with nickel barrier | Small end bushes |

| Al4.5Zn1Pb1Cu0.5Mg | Tri-metal | 55 | Al20Sn (sputter) with nickel barrier | Highly loaded conrod bearings |

Related internal links

to Metals

to Engine bearings