Main page

About us

Sliding Bearings Consulting

Advertising Opportunities

to Polymers

to Methods of polymers fabrication

Injection molding of polymers

Dr. Dmitri Kopeliovich

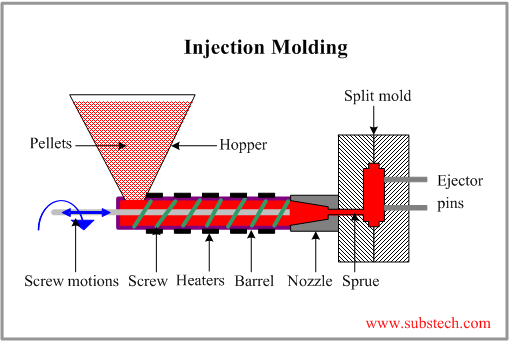

Injection Molding is a process in which molten polymer is forced under high pressure into a mold cavity through an opening (sprue).

Polymer material in form of pellets is fed into an Injection Molding machine through a hopper. The material is then conveyed forward by a feeding screw and forced into a split mold, filling its cavity through a feeding system with sprue gate and runners.

Injection Molding machine is similar to Extruder. The main difference between the two machines is in screw operation. In extruder screw rotates continuously providing output of continuous long product (pipe, rod, sheet). Screw of injection molding machine is called reciprocating screw since it not only rotates but also moves forward and backward according to the steps of the molding cycle.

It acts as a ram in the filling step when the molten polymer is injected into the mold and then it retracts backward in the molding step.

Heating elements, placed over the barrel, soften and melt the polymer.

The mold is equipped with a cooling system providing controlled cooling and solidification of the material.

The polymer is held in the mold until solidification and then the mold opens and the part is removed from the mold by ejector pins.

Injection Molding is used mainly for Thermoplastics, but Elastomers and Thermosets are also may be extruded. In this case cross-linking occurs during heating and melting of the material in the heated barrel.

A principal scheme of an Injection Molding Machine is shown in the picture.

Injection Molding is highly productive method providing high accuracy and control of shape of the manufactured parts. The method is profitable in mass production of large number of identical parts.

Thermoplastics commonly used in Injection Molding are as follows:

Injection Molding is used for manufacturing DVDs, pipe fittings, battery casings, toothbrush bases, bottle lids, disposable razors, automobile bumpers and dash boards, power-tool housing, television cabinets, electrical switches, telephone handsets, automotive power brake, automotive fascias, transmission, and electrical parts, mirror housings, steam irons, washer pumps, spoilers, butter tubs, moisture vaporizers, yogurt containers, toilet seats, cell-phone housings, cradles or bases for personal digital assistants, case of a notebook-computer, computer mouse, electrical connector housings, lawn chairs, automotive ashtrays, and cookware appliance handles and knobs, aerosol caps, household items, bottle caps, toys.

to top

Related internal links