Main page

About us

Sliding Bearings Consulting

Advertising Opportunities

to Polymers

to Methods of polymers fabrication

Extrusion of polymers

Dr. Dmitri Kopeliovich

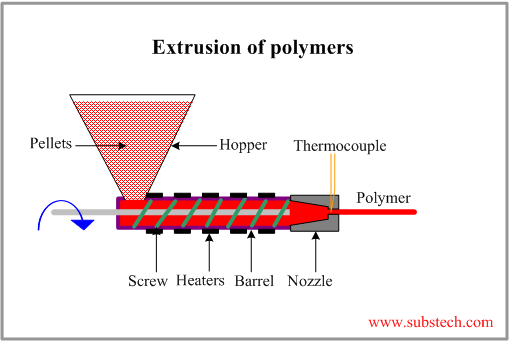

Extrusion is a process of manufacturing long products of constant cross-section (rods, sheets, pipes, films, wire insulation coating) forcing soften polymer through a die with an opening.

Polymer material in form of pellets is fed into an extruder through a hopper. The material is then conveyed forward by a feeding screw and forced through a die, converting to continuous polymer product.

Heating elements, placed over the barrel, soften and melt the polymer. The temperature of the material is controlled by thermocouples.

The product going out of the die is cooled by blown air or in water bath.

Extrusion of polymers (in contrast to extrusion of metals) is continuous process lasting as long as raw pellets are supplied.

Extrusion is used mainly for Thermoplastics, but Elastomers and Thermosets are also may be extruded. In this case cross-linking forms during heating and melting of the material in the extruder.

The thermoplastic extruded products may be further formed by the Thermoforming method.

A principal scheme of an extruder is shown in the picture.

Related internal links