Main page

About us

Sliding Bearings Consulting

Advertising Opportunities

to Composites

to Ceramic Matrix Composites

Fabrication of Ceramic Matrix Composites by Chemical Vapor Infiltration (CVI)

Chemical Vapor Infiltration (CVI) - description

Chemical Vapor Infiltration method of Ceramic Matrix Composites fabrication is a process, in which reactant gases diffuse into an isothermal porous preform made of long continuous fibers and form a deposition. Deposited material is a result of chemical reaction occurring on the fibers surface.

The infiltration of the gaseous precursor into the reinforcing ceramic continuous fiber structure (preform) is driven by either diffusion process or an imposed external pressure.

The deposition fills the space between the fibers, forming composite material in which matrix is the deposited material and dispersed phase is the fibers of the preform.

Chemical Vapor Infiltration (CVI) is similar to Chemical Vapor Deposition (CVD), in which deposition the forms when the reactant gases react on the outer substrate surface.

Chemical Vapor Infiltration is widely used for fabrication of silicon carbide matrix composites reinforced by silicon carbide long (continuous) fibers.

Commonly the vapor reagent is supplied to the preform in a stream of a carrier gas (H2, Ar, He). Silicon carbide (SiC) matrix is formed from a mixture of methyltrichlorosilane (MTS) as the precursor and Hydrogen as the carrier gas. Methyltrichlorosilane is decomposed according to the reaction:

CH3Cl3Si → SiC + 3HCl

The gaseous hydrogen chloride (HCl) is removed from the preform by the diffusion or forced out by the carrier stream.

Carbon matrix is formed from a methane precursor (CH4).

The ceramic deposition is continuously growing as long as the diffusing vapor is reaching the reaction surface.

The porosity of the material is decreasing being filled with the formed solid ceramic. However in the course of the CVI process the accessibility of the inner spaces of the preform is getting more difficult due to filling the vapor paths with the forming ceramic matrix.

The precursor transportation is slowing down. The growing solid phase separates the spaces in the material from the percolating network of the vapor precursor. Such inaccessible pores do not decrease any longer forming the residual porosity of the composite.

The matrix densification stops when the preform surface pores are closed. The final residual porosity of the ceramic composites fabricated by CVI method may reach 10-15%.

to top

Types of Chemical Vapor Infiltration process

Different versions of Chemical Vapor Infiltration process are classified into five types:

- Isothermal/isobaric (I-CVI) is the most commonly used type of CVI process. The fiber preform infiltrated in I-CVI process has no temperature gradient (kept at a uniform temperature). The reactant gas is supplied to the preform at a uniform pressure (no pressure gradient). I-CVI is a very slow process because of the low diffusion rate.

- Temperature gradient (TG-CVI). In this process the preform is kept at a temperature gradient. The vapor precursor diffuses through the preform from the cooler surface to the hotter inside regions. The temperature gradient enhances the gas diffusion. The precursor decomposes mostly in the hot inner regions since the rate of the chemical reaction is greater at higher temperatures. TG-CVI method allows better densification of the ceramic matrix due to prevention of early closing the surface pores.

- Isothermal-forced flow (IF-CVI) utilizes forced flow (pressure gradient) of the gas precursor penetrating into the uniformly heated preform. The rate of the ceramic matrix deposition is increased by the enhanced infiltration of the forced reactant gas.

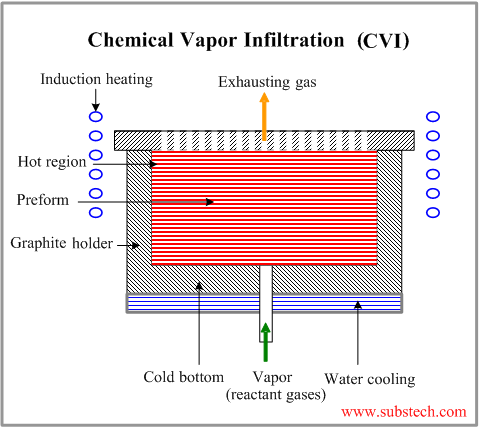

- Thermal gradient-forced flow (F-CVI) combines the effects of the both temperature gradient and forced flow (pressure gradient) enhancing the infiltration of the vapor precursor. A scheme of Chemical Vapor Infiltration process is shown in the picture below. The presented process combines both temperature gradient and pressure gradient for reduction of densification time. Temperature gradient in preform is achieved by heating the top region of it when the bottom region is cooled. Pressure gradient is determined by the difference in the pressures of the entering and exhausting gases.

- Pulsed flow (P-CVI). In P-CVI process the surrounding precursor gas pressure changes rapidly. The pressure changes in each cycle are repeated many times. A cycle of the pressure change consists of the evacuation of the reactor vessel followed by its filling with the reactant gas.

Chemical Vapor Infiltration (CVI) process

- Fabrication of the fiber preform.

- Application of a debonding interphase. A thin (commonly 0.1-1 µm) layer of pyrolytic carbon (C) or hexagonal boron nitride (BN) is deposited on the fiber surface by Chemical Vapor Infiltration (CVI) method.

- Infiltration of the preform with a preceramic gaseous precursor. The preform is heated and placed into a reactor with a gaseous precursor. The preform is infiltrated with the gas, which decomposes and forms a ceramic deposit (matrix) on the fiber surface. The process continues until the open porosity on the preform surface is closed.

- Abrading/machining the preform surface in order to open the paths of the percolating network, which allow further densification of the matrix.

- Multiple re-infiltration-abrading cycles until maximum densification is achieved.

- Protection surface coating. The open porosity is sealed in order to prevent a penetration of the environmental gases into the composite during the service. Additional layer protecting the composite surface from the oxidation may be applied over the sealcoat. The coatings are deposited by Chemical Vapor Infiltration (CVI).

Advantages and disadvantages of Chemical Vapor Infiltration (CVI) process

Advantages of fabrication of Ceramic Matrix Composites by Chemical Vapor Infiltration (CVI):

- Low fiber damage due to relatively low infiltration temperatures;

- Matrices of high purity may be fabricated;

- Low infiltration temperatures produce low residual mechanical stresses;

- Good thermal shock resistance;

- Increased Creep and oxidation resistance;

- Interphases may be deposited in-situ.

Disadvantages of fabrication of ceramic matrix composites by Chemical Vapor Infiltration (CVI):

- Slow process rate (may continue up to several weeks);

- High residual porosity (10-15%);

- High capital and production costs.

Related internal links