SubsTech’s sister website Smooth Sliding provides independent engineering consulting services that help you to solve engine bearing related issues: failures, material selection, geometry design and optimization of hydrodynamic conditions.

Smooth Sliding is an engineering consulting company run by Dr. Dmitri Kopeliovich:

- VP R&D of King Engine Bearings.

- World leading expert (32 years of experience) in design, technology and materials for Engine bearings in applications such as automotive, renewable energy, aviation, racing and others.

- Founder and owner of SubsTech (Substances & Technologies) – a leading professional website on Materials Science and Engineering.

- Author of numerous scientific and engineering publications and patents.

- Founder and owner of Smooth Sliding.

For further information and for requesting consulting services please visit our sister website Smooth Sliding.

to Metals

to Engine bearings

Manufacturing bi-metal strips for copper bearings

Dr. Dmitri Kopeliovich

The following processes are used for manufacturing bi-metal strips for copper based engine bearings:

Both processes are capable to produce the wide range of Copper based bearing materials.

Improperly sintered materials may be less strong than cast materials of the same composition due to possible voids and pores. The Grain structure of cast bearing alloys consists of copper dendrites oriented perpendicular to the bearing surface.

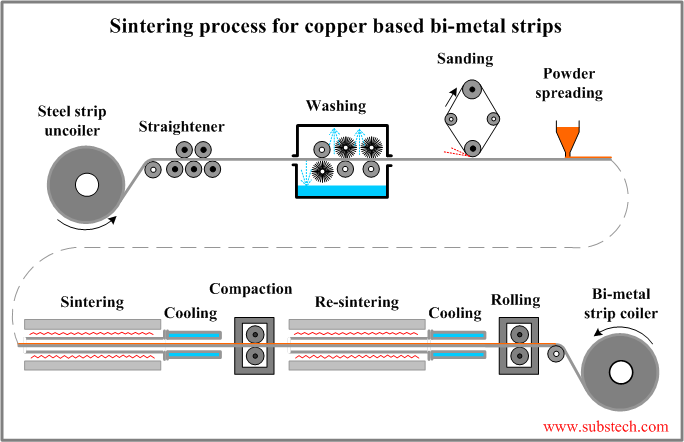

Sintering process for copper based bi-metal strips

The powder for sintering copper alloy is prepared by atomization of a melt of the alloy.

The sintering process includes the following stages:

- Uncoiling steel strip.

- Straightening the steel strip.

- Washing the strip by a hot alkaline solution and mechanical cleaning by rotating steel wire cylindrical brushes.

- Sanding the strip surface by an abrasive rotating endless belt.

- Spreading the powder of the copper alloy over the steel surface. The necessary powder alloy thickness is pre-calculated. The calculation takes into account two factors: the ratio between the densities of the powder and the sintered alloy and elongation of the strip as a result of Rolling.

- Sintering the powder. The process is performed in a long (about 33ft/10m) sleeve-type continuous sintering furnace. The sintering temperature is within the range 1515-1615°F(824-880°C) depending on the alloy composition. The atmosphere in the furnace is reducing: it consists of a mixture of Hydrogen (H2) and Nitrogen (N2), which may be prepared in Ammonia cracker by the process of dissociation of gaseous anhydrous Ammonia (NH3) according to the reaction: 2NH3 = N2 + 3H2. During the sintering process atmospheric hydrogen converts the oxides of copper (and other metals) on the surface of each powder particle into the metallic state (CuO + H2 = Cu + H2O). The particles then physically join (weld) to each other and to the steel strip due to the mutual diffusion of their atoms.

- Compaction. After sintering stage density of the alloy is higher than in the powder state but it is still 20-30% lower than in fully compact state. The pores between the joined particles are closed in the compaction stage when the strip passes a Rolling mill.

- Re-sintering. This stage is performed in order to set physical joining (welding) between the surfaces of the pores mechanically closed in the compaction stage. Re-sintering is conducted in a sintering furnace similar to that of the sintering stage. Parameters of the process are also similar to those of the sintering. As a result of re-sintering sound (no porosity) sinter structure of the copper alloy forms. The second phase (lead, bismuth) is homogeneously distributed throughout the copper based matrix in form of small particles (0.001-0.002”/25-50 μm) located between the copper grains.

- Rolling. This stage is performed in order to strengthen (strain hardening) both the steel back and the sintered cooper alloy.

- Recoiling the bi-metal strip.

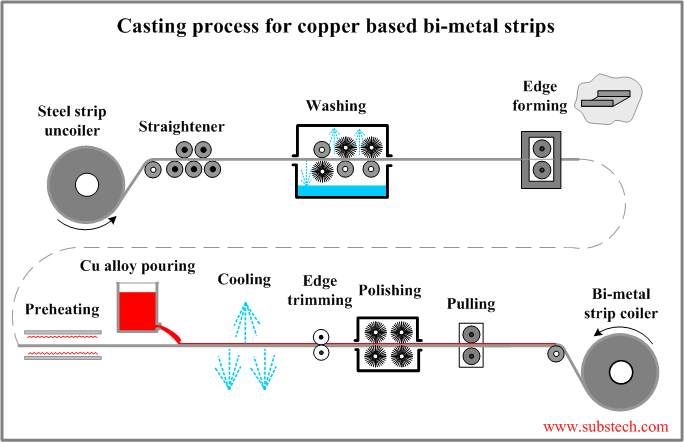

Casting process for copper based bi-metal strips

The casting process includes the following stages:

- Uncoiling steel strip.

- Straightening the steel strip.

- Washing the strip by a hot alkaline solution and mechanical cleaning by rotating steel wire cylindrical brushes.

- Edge forming. The strip edges are roll formed producing a shallow trough.

- Preheating the steel strip to about 1830°F(1000°C) in a reducing atmosphere preventing oxidation.

- Casting the copper alloy. The melt heated to 2280°F(1250°C) is poured onto the strip surface. A side leakage is prevented by the shaped edges.

- Cooling. The strip is sprinkled by water streams, which cools it down and cause Solidification of the copper alloy. The resulted cast structure of the copper alloy presents copper dendrites oriented perpendicular to the steel surface with the second phase particles (lead, bismuth) located between the dendrites arms.

- Edge trimming. The strip edges are slitted.

- Polishing the strip surfaces.

- Recoiling the bi-metal strip. The strip pulled by pinch rolls is coiled up.

Related internal links

to Metals

to Engine bearings