SubsTech’s sister website Smooth Sliding provides independent engineering consulting services that help you to solve engine bearing related issues: failures, material selection, geometry design and optimization of hydrodynamic conditions.

Smooth Sliding is an engineering consulting company run by Dr. Dmitri Kopeliovich:

- VP R&D of King Engine Bearings.

- World leading expert (32 years of experience) in design, technology and materials for Engine bearings in applications such as automotive, renewable energy, aviation, racing and others.

- Founder and owner of SubsTech (Substances & Technologies) – a leading professional website on Materials Science and Engineering.

- Author of numerous scientific and engineering publications and patents.

- Founder and owner of Smooth Sliding.

For further information and for requesting consulting services please visit our sister website Smooth Sliding.

to Metals

to Engine bearings

Engine bearing materials

Dr. Dmitri Kopeliovich

Most engine bearings have layered structure, which provides optimum combination of the bearing material properties: fatigue strength (load capacity), seizure resistance (compatibility), wear resistance, conformability, embedability, corrosion resistance, cavitation resistance.

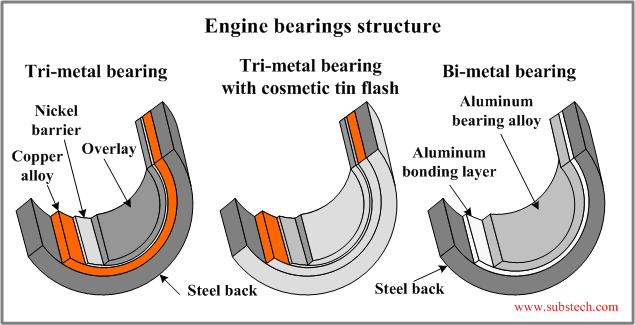

According to the number of the main functional bearing layers the bearings may be mono-metal (solid), bi-metal, tri-metal or multi-layer.

Most engine bearings are either bi-metal or tri-metal.

Typical engine bearings structures are presented in the figure below.

Engine bearing layers and their functions

- Steel back supports bearing structure, provides its rigidity and press fit under severe conditions of increased temperature and cycling loads.

Steels SAE 1008, SAE 1010 and SAE 1020 are used for steel back of engine bearings.

- Intermediate layer (lining) is a layer located between the steel back and the overlay.

Intermediate layer is made of a bearing material with moderate or low anti-friction properties (conformability, compatibility, embedability) but high fatigue strength providing durability of the bearing working under alternating loads generated by the internal combustion engine.

A certain level of surface (anti-friction) properties is necessary for preventing catastrophic failure of the bearing in emergency conditions of boundary lubrication, oil starvation, significant misalignments or shaft deflections. Intermediate layer is referred to tri-metal and multi-layer bearings.

Intermediate layers are made mainly of Copper alloys such as CuPbSn (leaded bronzes), CuAl (aluminum bronze), CuBiSn. Copper based intermediate materials, CuSnNi, CuZn are applied on the steel back surface by either casting or sintering process.

Some Aluminum alloys such as Al-6Sn, Al-11Si, Al-4Si are also used as intermediate layer materials. Aluminum based bearing materials are bonded to the steel back by the cold rolling boding method.

Thickness of intermediate layers is usually within the range 0.008”-0.020” (0.2-0.5 mm).

- Engine bearing overlay is a thin (0.0005”-0.001” / 12-25 µm) surface layer made of a soft material (PbSnCu, SnCu, PbIn, graphite/molybdenum disulfide polymer based materials) possessing very good ant-friction properties (seizure resistance (compatibility), conformability, embedability).

Overlays are referred to tri-metal bearings. An overlay is applied to the surface of the bearing intermediate lining after final machining operation (boring or broaching).

Overlay properties become crucial particularly under the conditions of boundary lubrication at low rotation speeds of the engine (engine start and shutdown).

Low thickness of overlays is necessary for achieving required level of fatigue strength is dependent on the overlay thickness (the thicker the overlay the lower its fatigue limit).

Types of engine bearing overlays:

Lead based engine bearing overlays

Tin based engine bearing overlays

Sputter bearing overlays

Polymer based engine bearing overlays

- Nickel diffusion barrier (nickel dam) is deposited between the intermediate layer and the overlay in order to prevent a migration of tin from the overlay into the intermediate material (copper).

Diffusion of tin into copper causes formation of brittle Cu-Sn intermetallic compounds (Cu3Sn, Cu6Sn5), which decrease the adhesion strength of the overlay to the intermediate layer. In addition to this decrease of the tin content in the overlay due to the migration into the intermediate material deteriorates the Corrosion resistance of the lead-based overlay alloy.

Thickness of nickel diffusion barrier is about 0.00004”-0.00006” (1-1.5 µm).

Nickel electroplating methods are used for the diffusion barrier deposition. If the overlay is coated by Physical vapor Deposition (sputter bearings) the nickel barrier is also applied by the vapor deposition method.

- Bonding layer is used for good adhesion between the steel back and aluminum-tin alloy.

Presence of tin particles on the surface of an aluminum-tin alloy bonded to a steel strip weakens the adhesion strength between the materials.

A bonding layer of pure aluminum between the AlSn alloy and steel allows to achieve strong adhesion.

Pure aluminum is commonly bonded to the aluminum-tin alloy and then the aluminum strip is bonded to steel back. The thickness of the aluminum bonding layer in a bearing is about 0.001”-0.002” (25-50 µm).

Another type of bonding layer is a nickel layer deposited on the steel surface prior to bonding with aluminum-tin alloy.

- Non-plated bearing material is referred to mono-metal (solid) and bi-metal bearings.

No overlays are deposited on the surface of the material. Non-plated materials combine fair surface (anti-friction) properties with good fatigue strength.

Most aluminum-tin bearing alloys (Al20Sn1Cu, Al12Sn3Si1Cu) do not require overlays.

Aluminum-tin alloys are bonded to the steel back by the cold rolling boding method.

Thickness of non-plated bearing alloys in is usually within the range 0.008”-0.016” (0.2-0.4 mm).

- Tin flash is a very thin (max. 0.00004”/1µm) layer of tin applied to the overall bearing surface.

Tin flash improves cosmetic appearance of the bearing and imparts additional corrosion protection.

Tin alloy electroplating methods are used for tin flash deposition.

to top

Classification of engine bearing materials

-

- Mono-metal (solid) bearings (eg. Al11Si)

- Bi-metal bearings

- Soft tin containing alloys (AlSn)

- Non-heat-treatable (solid solution hardened) tin containing alloys (AlSnSi, AlSnNiMn)

- Heat-treatable (dispersion hardened) tin containing alloys

- Tri-metal bearings

- Tin containing alloys (Al6Sn)

- Soft metal overlay

- No tin, silicon containing alloys (Al4Si, Al11Si, AlZnMg)

- Soft metal overlay

- Sputter bearing overlays (eg. Al20Sn, Al40Sn)

-

- Mono-metal (solid) bearings

- Bi-metal bearings (Cu10Pb10Sn, CuAl)

- Cast copper alloy

- Sintered copper alloy

- Tri-metal bearings (CuPbSn, CuBi)

- Cast copper alloy

- Sputter bearing overlays (eg. Al20Sn, Al40Sn)

- Sintered copper alloy

- Soft metal overlay (eg. PbSnCu, SnCu)

- Multi-layer bearings

- Two different metallic overlays (eg. NiSn+SnCu)

- Soft metal overlay + Graphite/Molybdenum disulfide containing polymer based overlay

Related internal links

to Metals

to Engine bearings