Main page

About us

Sliding Bearings Consulting

Advertising Opportunities

to Polymers

to Methods of polymers fabrication

Blow molding

Dr. Dmitri Kopeliovich

Blow Molding is a process in which a heated hollow thermoplastic tube (parison) is inflated into a closed mold conforming the shape of the mold cavity.

The most widely used materials for Blow Molding are:

Disposable containers of various sizes and shapes, drums, recyclable bottles, automotive fuel tanks, storage tanks, globe light fixtures, toys, tubs, small boats are produced by Blow Molding method.

There are three principal techniques of Blow Molding, differing in the method by which parisons are prepared:

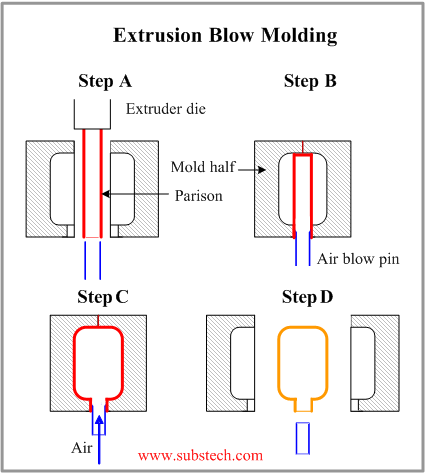

Extrusion Blow Molding

Extrusion Blow Molding involves manufacture of parison by conventional extrusion method using a die similar to that used for extrusion pipes.

Extrusion Blow Molding is commonly used for mass production of plastic bottles.

The production cycle consists of the following steps:

- The parison is extruded vertically in downward direction between two mold halves.

- When the parison reaches the required length the two mold halves close resulting in pinching the top of parison end and sealing the blow pin in the bottom of the parison end.

- Parison is inflated by air blown through the blow pin, taking a shape conforming that of the mold cavity. The parison is then cut on the top.

- The mold cools down, its halves open, and the final part is removed.

Injection Blow Molding

In Injection Blow Molding method a parison is produced by injecting a polymer into a hot injection mold around a blow tube or core rod.

Then the blow tube together with the parison is removed from the injection mold and transferred to a blow mold.

Following operations are similar to those in the extrusion blowing molding.

Injection Blow Molding is more accurate and controllable process as compared to the Extrusion Blow Molding.

It allows producing more complicated products from a wider range of polymer materials.

However production rate of Injection Blow Molding method is lower than that of Extrusion Blow Molding.

to top

Stretch Blow Molding

Stretch Blow Molding is similar to Injection Plow Molding.

Stretch Blow Molding involves injection molding of a parison, which is then stretched in the downward direction by means of the blow tube.

The extended parison is then inflated in a blow mold.

In this method biaxial molecular orientation is produced. The specific molecular orientation provides higher mechanical strength, rigidity and transparency of the material.

Material, commonly used in this method is Polyethylene Terephtalate (PET).

Stretch Blow Molding is used for manufacturing containers for carbonated beverages.

to top

Related internal links