Main page

About us

Sliding Bearings Consulting

Advertising Opportunities

to Ceramics

to Applications of ceramics

Thermal barrier coatings

Dr. Dmitri Kopeliovich

Thermal barrier coatings (TBC) are ceramic layers deposited over metallic parts in order to provide their thermal insulation from the combustion gases.

Thermal barrier coatings allow to achieve higher efficiency of combustion engines (internal combustion engines and gas turbine engines) due to an increase of their operating temperature.

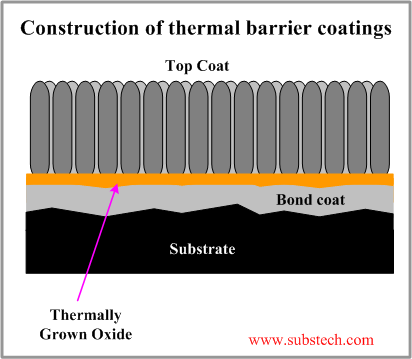

Construction of thermal barrier coatings

A thermal barrier coating is generally composed of two layers:

- Metallic Bond Coat with a thickness of about 0.004” (0.1 mm). The alloy of the bond coating is MCrAlY, where M is Ni, Fe or Co. The bond coat is an intermediate layer providing strong adhesion of the outer ceramic layer to the substrate surface. The bond coat also inhibits the diffusion of the substrate and the ceramic coating components. Aluminum in the amount of about 10% in the bond coat is required for a formation of an oxide barrier (thermally grown oxide) on the interface between the bond coat and the ceramic layer. The thermally grown oxide form as a result of oxidation of the bond coat with Oxygen diffusing from the combustion gases throghout the ceramic layer. The oxide layer is composed of α-Al2O3.

- Outer ceramic layer (Top Coat). Commonly 6-9% yttria (Y2O3) stabilized zirconia (ZrO2) with tetragonal crystal structure is used for building the outer ceramic layer. Yttria is added to zirconia in order to stabilize the tetragonal structure. Without a stabilizing agent tetragonal zirconia transforms to monoclinic allotrope stable at low temperatures. The volume change (about 8%) resulting from the tetragonal-monoclinic transformation causes internal stresses and cracking. Monoclinic zirconia is also undesirable because of its low Coefficient of Thermal Expansion and poor mechanical properties. Tetragonal zirconia is characterized by:

- Low thermal conductivity (about 2 W/(m*K));

- High Coefficient of Thermal Expansion which allows reducing thermal stresses at the boundary with the metallic substrate;

- Relatively high Fracture Toughness;

- High thermal shock resistance.

Methods of depositing thermal barrier coatings

Most of thermal barrier coatings are deposited by one of the two techniques:

Most of thermal barrier coatings are deposited by one of the two techniques:

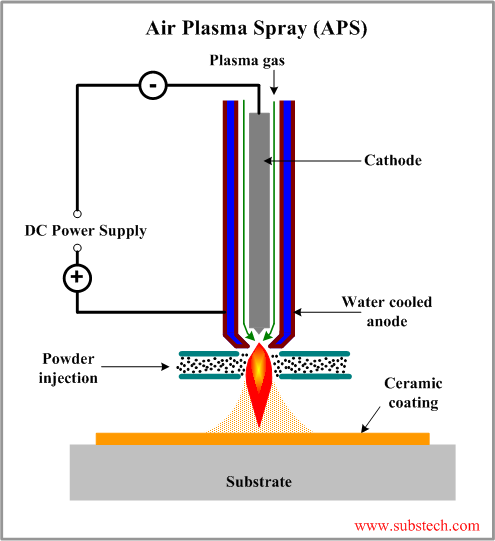

- Air Plasma Spraying (APS).

The method utilizes an electrical arc ionizing Argon flowing through it and converting into hot plasma at a temperature of about 15,000°F (8,300°C).

The ceramic material in powdered form is injected into the plasma jet where the ceramic grains melt and move in the stream of the hot gas towards the substrate surface.

When the molten particles impact the substrate surface they solidify in form of splats (flattened discs).

The resulting microstructure is composed of the grains and elongated pores stretched in the direction parallel to the substrate surface.

- Electron Beam Physical Vapor Deposition (EB-PVD).

In EB-PVD technique an electron beam is directed to the target made of the ceramic material.

The electrons bombard the target and vaporize the material, molecules of which are accelerated towards the substrate surface.

The ceramic material deposits on the surface in form of parallel columns oriented perpendicualar to the substrate surface.

Because of its columnar structure the coatings produced by the method of electron beam physical vapor deposition have the thermal conductivity 30-40% higher than that of the coatings deposited by Air Plasma Spraying.

On the other hand the columnar structure is more tolerant to the stresses generated by thermal expansion of the coating.

Thermal barrier coatings in gas turbine engines

Combustion chamber and blades of a gas turbine engine operate at high temperatures of about 2000°F (1093°C). The nickel base superalloys at such high temperatures are exposed to Creep and oxidation.

Thermal barrier coatings with the thickness allow to increase the service life of the turbine gas engine elements due to the protection of the metallic surface from oxidation and reduction of the substrate temperature by 212-500°F (100-260°C).

The directing blades, nozzle vanes and other elements of the combustion chambers are commonly coated by Air Plasma Spraying method.

The rotating blades are coated by Electron Beam Physical Vapor Deposition since the columnar grain structure of the coating is preferrable in the conditions of high thermallly induced stresses.

to top

Thermal barrier coatings in internal combustion engines

Maximum efficiency of a heat engine is:

ηmax = 1 - Tc/Th

where:

Tc - temperature of the cold sink (cooling media), K;

Th - temperature of the hot source (combustion chamber), K.

According to the expression higher combustion temperature results in better theoretical efficiency of the engine.

In addition to this higher temperature causes the fuel burning to be more complete, which also increases the engine efficiency.

Higher temperature in the combustion chamber improves the engine efficiency.

The efficiency of conventional diesel engines is about 40%. 30% of the combustion gases energy is removed by the cooling system of the engine.

Thermal barrier coatings may increase the useful engine energy due to a reduction of the coolant energy.

The temperature of the combustion gases in a conventional diesel engine without thermal barrier coating is about 932°F (500°C). It may be increased up to 1472°F (800°C) by using a ceramic coatings over the diesel combustion chamber surface. The coating thickness is of order of 0.04” (1 mm).

Application of thermal barrier coatings in turbocharged diesel engines allows to increase the combustion gases temperature 2012°F (1100°C). At such high temperatures not only the engine efficiency is improved but also the content of the pollutants in the exhausting gases is reduced.

The main benefits of thermal barrier coatings in diesel engines:

- Higher engine efficiency;

- Lower pollutant emission;

- Lower fuel consuption;

- Low cetane fuels may be used;

- Smaller ignition delay;

- Lowe size and weight of the engine.

Related internal links