to Ceramics

to Applications of ceramics

Tribological properties and applications of alumina

Dr. Dmitri Kopeliovich

Content

1. Introduction

This review is an attempt to consider the tribological aspects of alumina from the practical engineering point of view.

The oldest anti-friction application of aluminum oxide is the jewel bearings, in which alumina is used in its monocrystalline form (sapphire, ruby, corundum). Jewel bearings have been used in mechanical watches (17 jewels watches) and high-precision instruments since 1704.

The coefficient of friction of sapphire is 0.10-0.20, which is comparable with that of Solid lubricants (coefficient of friction of graphite is 0.1). Sapphire is also extremely hard and wear resistant. Excellent tribological properties of monocrystalline aluminum oxide present a great potential for its polysrystalline form as anti-friction material.

Polycrystalline alumina has been used in tribological applications for years due to its unique combination of properties: wear resistance, chemical and thermal stability, stiffness, biocompatibility and low weight. However the tribological applications of alumina are still limited in spite of the extensive scientific activities in this field and evident potential benefits.

to top

2. Tribology

Tribology is the science and engineering of rubbing surfaces.

2.1 Friction

Friction is the resistance to sliding motion. There are two types of friction mechanisms:

- Adhesive friction caused by physical or chemical bonding between the opposing microasperities on the rubbing.

- Deformation friction caused by interlocking of the opposing microasperities followed by their displacement.

Friction force F is proportional to the normally applied load W:

F = µ*W

where µ - the coefficient of friction.

2.2 Lubrication

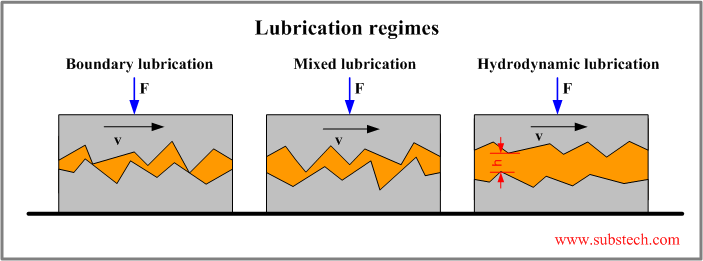

The ratio of the squeeze film (oil film) thickness h to the surface roughness Ra determines the character of the contact between the microasperities on the friction surfaces and the type of the lubrication regime (Fig.1):

Fig.1 Lubrication regimes

Lubrication regimes:

- Boundary lubrication (h<Ra) : a constant contact between the mating surfaces.

- Mixed lubrication (h~Ra): intermittent contacts.

- Hydrodynamic lubrication (h>Ra): no contact.

2.3 Wear

Wear may combine effects of various physical and chemical processes proceeding during the friction between two counteracting materials: micro-cutting, micro-plowing, plastic deformation, cracking, fracture, fatigue, welding, melting, chemical interaction.

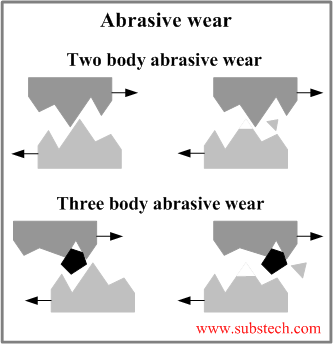

The two modes of abrasive wear are illustrated in the Fig.2.

Fig.2 Abrasive wear

2.4 Tribology of alumina

Alumina ceramics like other Ceramics are brittle, and the prevailing mechanism of their wear is abrasion by microfracture mode, which is characterized by a formation of cracks in the subsurface regions surrounding the wear groove. It is different from Metals wearing mainly by adhesive mechanism when a strong metallic bonding forms between the contacting microasperities and from Polymers dominating wear mechainism of which is abrasion caused by plowing and cutting actions.

Tribological characteristics and mechanism of wear of alumina were studied by S. Jahanmir and X. Dong [1]. The authors showed that the tribological performance of alumina is controlled by one of the four different mechanisms: tribochemical reaction, plastic flow and plowing, microfracture and formation of glassy surface film. It was also concluded that increase of the fracture toughness, modification of the boundary phase composition and lowering the coefficient of friction will improve the tribological performance of alumina.

to top

3. Factors affecting the tribological properties of alumina

Characteristics of friction and wear of alumina are determined by the combination of its bulk microstructure parameters, surface quality and environmental factors and lubrication conditions [2].

3.1 Effect of microstructure

The main disadvantage of Ceramics as compared to Metals and Polymers is their low fracture toughness.

Toughness is a bulk mechanical property of a material however it correlates with its wear resistance particularly when the wear is a result of abrasive action caused by cracking.

Finer grain structure results in increased toughness and better wear resistance.

Grain size also determines the surface finish quality, which may be achieved by grinding and polishing operations.

Fine grain structure allows to decrease the size of the surface microasperities after the surface finish operation resulting in lower coefficient of friction.

- Critical flaw size (the size of a flaw that results in rapid fracture)

Effect of flaw size on the fracture strength of a ceramic material is expressed by the Griffith equation:

σC =KIC /(Y(π a)½)

where:

KIC – stress-intensity factor, measured in MPa*m½;

a – the flaw size;

Y – geometry factor.

According to the equation flaws of lower size result in increased material toughness and higher wear resistance.

Flaw size is generally proportional to the grain size.

- Homogeneity

Homogeneous distribution of alumina particles size and pores size, second phase particles (toughening particles) incorporated between the matrix particles, aid phase (binders, etc.) locating at the grains boundaries results in lowering the flaw size and consequently in increase of the fracture strength (according to the Griffith equation).

Higher fracture strength causes higher wear resistance.

Bulk homogeneity of the microstructure allows creating fine and homogeneous surface finish with low content of surface flaws.

High quality surface possess low coefficient of friction.

3.2 Manufacturing processes forming microstructure of alumina ceramics

Powder characteristics such as particle shape (spherical, irregular), average particle size, size distribution determine the alumina grain size and the amount and size of the pores.

The value of the applied pressure, the method of its application (Uniaxial (Die) Pressing, Isostatic Pressing, Injection Molding, Extrusion, Slip Casting, etc.) and the amount of binders and other additives (plasticizers, lubricants, deflocculants, water etc.) determine the pores size and the residual internal stresses.

Diffusion proceeding during sintering process causes the pores to diminish or even to close up resulting in densification of the alumina ceramic material.

The bonding and other second phases are distributed between the grains of the main ceramic phase.

The matrix grains may grow during the sintering process. Thus sintering process determines the final alumina grains and pores sizes and the physical and the chemical homogeneity.

3.3 Effect of surface characteristics on tribological properties of alumina ceramics

- Surface topography

Friction characteristics (coefficient of friction, wear) are strongly dependent on the type of the lubrication regime (boundary lubrication, mixed lubrication, hydrodynamic lubrication).

The lubrication regime is determined by the ratio of the lubricant film thickness to the surface roughness Ra.

Rough ceramic surface with relatively large microasperities causes direct contact between the rubbing surfaces and results in high coefficient of friction and increased wear.

High surface finish quality allows to improve the tribological characteristics of alumina.

Ceramics are brittle and they wear by fracture mechanism, which is characterized by formation of cracks in the subsurface regions surrounding the wear groove. The volume of the lost material is higher than the volume of the wear track.

Thus wear of brittle ceramics results in roughening the surface. The effect of roughening during friction is lower in toughened ceramics.

- Surface defects

Sintering defects, surface machining, impacts during friction, embedded particles introduce surface flaws, which lead to fracture cracking and increase wear.

- Surface composition and tribochemical reactions

Ceramic surface may adsorb molecules of the environmental gases and liquids. Such surfaces with modified composition may have different coefficient of friction.

Coefficient of friction of alumina in vacuum is commonly higher than that in air.

Hydration of Alumina ceramics in a humid atmosphere also results in changing their coefficients of friction and wear. Wear of hydrated Alumina ceramics is increased due to chemisorption embrittlement.

Methods of modification of ceramic surfaces:

- Plasma oxidizing - a method of surface oxidation by elemental Oxygen supplied to the ceramic surface by plasma.

- Ion nitriding and carburizing - a method of introducing nitrogen (nitriding) or carbon (carburizing) atoms into the ceramic surface by means of plasma (glow-discharge).

- Ion implantation - a method of introducing a material into a ceramic surface by electrostatically accelerated ions.

- Laser densification - a method of heating the ceramic surface layer by a laser beam resulting in closing the pores between the ceramic powder particles.

- Electron beam densification - a method of heating the ceramic surface layer by an electron beam resulting in closing the pores between the ceramic powder particles.

- Chemical etching - cleaning the ceramic surface by acids.

- Sputter etching - bombarding the ceramic surface by accelerated plasma ions, which vaporize the surface molecules.

3.4 Effect of lubrication

Lubricants decrease coefficient of friction and reduce wear of the rubbing parts.

Lubricants remove the heat generated by friction. This function is particularly important for ceramics since they have lower thermal conductivity and usually produce more heat due to relatively high coefficient of friction.

Lubricants remove wear debris from the rubbing surfaces.

Lubricants also protect the ceramic surface from the environment.

- Liquid lubricants

Liquid hydrocarbon lubricants are commonly used for relatively low temperatures (up to 392ºF/200ºC). Silicone oils may be used up to 570ºF (300ºC).

Solid lubricants may be used for lubricating alumina ceramics in various forms: suspensions in liquid lubricants, dry powders, Dispersions in gases, coatings.

Requirements to solid lubricants properties: good adhesion to the ceramic surface, low shear strength in the sliding direction and high compression strength in the direction of the load (perpendicular to the sliding direction).

Substances used as solid lubricants: graphite, molybdenum disulfide, boron nitride, Polytetrafluoroethylene (PTFE), calcium fluoride-barium fluoride eutectic.

Maximum work temperature some of the solid lubricants is low (PTFE: 392ºF/200ºC). Other lubricants may withstand up to 1508ºF/820ºC (calcium fluoride-barium fluoride eutectic).

- Gaseous lubricants

Vapors of some organic substances may serve as lubricants for alumina. The vaporized molecules of such lubricant reach the ceramic surface react with it and form on its surface a film possessing low coefficient of friction.

to top

4. Self-lubricating alumina matrix composites

Liquid lubrication allows dramatically decrease the coefficient of friction of Alumina ceramics.

Solid lubricants continuously supplied to the rubbing ceramic surface have a similar effect. However use of lubricants is impossible in the applications in which the ceramic part operates under the conditions of high temperature, vacuum or corrosive environment.

Continuous supply of a solid lubricant to the ceramic surface may be provided by the ceramic material itself if it is a composite material with the alumina matrix containing dispersed particles of the lubricant (self-lubrication).

During the friction action the solid lubricant smears over the contact surface and forms a transfer film reducing the coefficient of friction.

Solid lubricants, which are used or may be potentially used in self-lubricating alumina matrix composites:

- Sulphides, selenides and tellurides (chalcogenides) of metals (eg., Molybdenum disulfide)

- Oxides: B2O3, MoO2, ZnO, Re2O7, TiO2, CuO.

- Soft metals (bismuth, tin, silver, indium, lead).

Examples of self-lubricating ceramic composites:

- Alumina-graphite composite

Graphite is a solid lubricant relating to the class of Inorganic lubricants with lamellar structure.

The layered structure allows sliding movement of the parallel planes.

Alumina-graphite composite may be prepared by Isostatic Pressing.

According to [3] fine grain alumina-20%graphite composite has the coefficient of friction 0.25, which is a half of that of a pure alumina ceramic.

- Alumina-carbon nanotube composite

Carbon nanotubes are carbon allotropes having cylindrical (tube-like) crystal structure.

Hot pressed alumina-CNT composites have higher fracture toughness than monolithic alumina ceramic due to the ability of the nanotubes to absorb energy through their highly flexible elastic behavior during deformation [4].

Increase of CNT content from 0 to 12% caused reduction of the coefficient of friction from 0.5 to 0.3. The lubricating effect of CNT in the composite is explained by the rolling motion of the nanotubes over the contacting surface [5].

- Alumina-CaF2 composite

Calcium difluoride (CaF2) (fluorite, fluorospar) possesses lubrication properties and can be used as solid lubricant operating at increased temperatures 750-1750°F (~400-950°C).

Tribological behavior of hot pressed composites: Al2O3-TiC matrix containing up to 15% of calcium fluoride was investigated in [6].

It was found that CaF2 releases and smears on the contacting surface acting as a solid lubricant. Presence of calcium fluoride in the composite causes decrease of the coefficient of friction. Wear rate of the ceramic composites also decreases with the increase of the CaF2 content up to 10%.

The lubrication effect of CaF2 in alumina and alumina-silver based composites was studied in [7]. It was found that calcium fluoride causes reduction of the coefficient of friction only in the temperature range 200-650°C (392-1202°F) due to formation of a waell-covered solid lubricating film.

- Nano-structured alumina-FeS composite

FeS (Iron (II) sulfide, ferrous sulfide) has the hexagonal crystal structure similar to that of Graphite hexagonal boron nitride and molybdenum disulfide.

Materials having hexagonal crystal structure are characterized by low shear strength and therefore low coefficient of friction.

Investigation of the tribological effect of FeS in the plasma sprayed nano-structured alumina-titania-FeS composite coating [8] showed that the coefficient of friction is decreasing with the increase of the FeS content up to 40-50%.

The wear rate of the composite containing FeS is lower than that of single FeS and of Al2O3-TiO2 ceramic.

to top

5. Wear resistant alumina coatings

Wear is the removal of the material from the surface of a solid body as a result of mechanical action of the counterbody.

Wear is one of the main causes of failing mechanical systems.

Wear of a metallic, polymeric or ceramic part may be considerably reduced by applying a wear resistant coating over the part surface.

Alumina ceramics have an excellent resistance to different types of wear due to their high strength and hardness, which are determined by the strong ionic bonding between the atoms.

Besides to high wear resistance and hardness alumina coatings impart the substrate corrosion and thermal protection.

The following techniques are used for deposition of wear resistant alumina coatings:

5.1 Wear resistant alumina coatings applied by Plasma Spraying (PS)

Plasma Spraying is the most widely used method for applying wear resistant alumina coatings.

Plasma spraying uses a DC arc struck between two non-consumable electrodes for ionization of an inert gas delivered to the arc region.

Ionized gas (plasma) heats, melts and accelerates the coating material (alumina) fed to the plasma torch in form of powder.

The wear resistance and other properties of the alumina coatings deposited by Plasma Spraying are primarily determined by the porosity of the resulted coating and the alumina grains size.

Plasma Spraying permits to manufacture coatings with sub-micrometer or even nanometer scale structure [9].

Depending on the spraying process parameters the coatings structures from dense to 20% porosity may be obtained.

The alumina coating properties (wear resistance, coefficient of friction, fracture toughness) may be improved by incorporating other ceramic particles into the alumina matrix.

Addition of SiC in alumina matrix results in a decrease of the coating friction coefficient.

Al2O3-ZrO2 exhibits a better wear resistance than pure Al2O3 [9].

Effect of temperature on the wear resistance and the coefficient of friction of alumina-3%titania coating deposited by plasma spray process was studied in [10]. The results show that above 572ºF (300ºC) the friction coefficient decreases due to softening of coating material. The wear rate increases with increase in temperature. The coating showed brittle fracture at higher temperature.

5.2 Wear resistant alumina coatings applied by High Velocity Oxygen Fuel (HVOF) spraying

High Velocity Oxygen Fuel (HVOF) involves a combustion heat of the mixture of a high pressure fuel gas (propane or acetylene) with Oxygen burning of which produces a flame of supersonic velocity.

The coating material (alumina) in form of powder is fed to the spraying gun where it is melted, atomized by the compressed air and ejected to the substrate surface.

According to [11] HVOF has the following advantages compared to the Plasma Spraying (PS) coating:

1)high particle velocity (above 5 Mach) renders a dense coating with higher adhesive and cohesive strength;

2)low surface roughness;

3)less thermally induced changes are generated in the coating material.

The disadvantage of HVOF alumina coating is low density due to incomplete melting of the alumina particles.

However, as shown in [12], when temperature and normal load increase, making brittle cracking a significant wear mechanism, HVOF coatings become superior to Atmospheric Plasma Spraying (APS) ones, thanks to higher toughness. In dry particles abrasion, brittle fracture prevails; therefore, the tougher HVOF coatings outperform APS ones.

5.3 Wear resistant alumina coatings applied by Physical Vapor deposition

Physical Vapor Deposition (PVD) is the process involving vaporization of the coating material in vacuum, transportation of the vapor to the substrate and condensation of the vapor on the substrate (part) surface.

Two PVD techniques are used for depositing wear resistant alumina coatings: Sputtering and Electron Beam Physical Vapor Deposition (EB-PVD).

Sputtering is a Physical Vapor Deposition method utilizing argon ions for bombarding a cathodically connected target made of the coating material. Atoms of the target are knocked out by the high energy ions and deposit on the substrate surface.

In the EB-PVD method the target anode is bombarded in high vacuum with an electron beam generated by a charged tungsten filament. Electron Beam evaporation method is much faster than sputtering. According to [13] the sputtering process takes approximately 50 hours to prepare a 0.24-0.31 mil (6-8 µm) thick alumina film compared to only 20 minutes needed for the E-beam evaporation.

Typical alumina coating obtained by the Electron Beam Physical Vapor Deposition methods has a columnar structure.

Dense fine grain crack-free structure of PVD deposited alumina coatings does not requires post deposition polishing and provides low wear rate. It is shown in [14] that the wear characteristics of the foil air bearings are greatly improved by applying a protective sputter deposited Al2O3 coating.

5.4 Wear resistant alumina coatings applied by Chemical Vapor deposition (CVD)

Chemical Vapor Deposition (CVD) is the process in which the coating is formed on the hot substrate surface placed in an atmosphere of a mixture of gases as a result of a chemical reaction or decomposition of the gases on the substrate material.

Alumina CVD coatings are used in multilayered coatings on cemented carbide cutting tools.

Alumina has an excellent resistance to the diffusion and oxidation wear, which is particularly important for high speed cutting tools.

The most common crystallographic variations of CVD alumina are the stable alpha-Al2O3 and the metastable (i.e. stable at room temperature, but not so at machining temperatures) kappa-Al2O3. The grain shape of alpha-Al2O3 is columnar in the growth direction; the density of dislocations and pores is large and voids are frequent in grain boundaries in comparison to kappa-alumina. Kappa-alumina coatings are fine-grained and mainly dislocation free [15].

5.5 Wear resistant alumina coatings prepared from ceramic slurry

Slurry is a stable suspension consisting of ceramic (alumina) powders, processing additives and 20-35% of liquid (water or solvent).

The slurry is spread (sprayed) over the substrate surface and then cured at 250-900ºF (121-482ºC).

Alumina slurry coatings are widely used as a thermal barrier on the gas turbine surfaces.

According to [16] alumina slurry coating has performed successfully on an aluminum internal combustion engine. The cylinder liners coated with alumina possess good thermal and tribological properties providing reduction in cooling requirements, lower friction and wear, reduced emissions and higher durability.

5.5 Wear resistant alumina coatings applied by Sol-Gel method

Sol-Gel process is a synthesis of an oxide ceramic (alumina) in a liquid solution of an alkoxide based precursor in which submicron particles of a solid phase suspended in the liquid (Sol) are obtained and then condensed forming Gel - a 3-D network of polymerized macromolecules surrounded with the solution.

Easy and cheap sol-gel method is commonly used for preparation of alumina coatings.

Wear and friction of alumina films on silicon wafers prepared by the sol-gel method using dip-coating technique were investigated in [17]. It was shown that the friction coefficients in the range of temperatures 572-1652ºF (300-900°C) were on the level of 0.18-0.23 while at the temperature of 1832ºF (1000°C) the friction coefficient increased up to 0.39.

5.6 Wear resistant alumina coatings applied by anodizing

Anodizing is the electrochemical process of growing conversion oxide coating as a result of oxidation of an anodically connected metal in an acidic electrolyte solution.

Aluminum and Aluminum alloys form an alumina film when exposed to air. The film is extremely thin and poorly adherent to the aluminum surface therefore it can not serve as a protective and wear resistant coating.

Alumina films prepared by the anodic oxidation of aluminum have excellent adhesion to the substrate surface. Anodized alumina coatings have high hardness, which provides good wear resistance. Columnar porosity characteristic for the anodized oxide film helps in retaining Lubricants and leads to reducing coefficient of friction.

The authors of [18] state that the main application of such an oxide layer is cylinder bearing surfaces in non-lubricated air-compressors. The oxide layer sliding over rings made of polytetrafluoroethylene (PTFE) with a graphite filler demonstrated very low friction coefficient μ = 0.08.

to top

6. Tribological properties of alumina reinforced composites

Composite materials reinforced (filled) with ceramic particles/fibers (e.g., alumina) are extensively used in the applications in which tribological properties (wear rate, coefficient of friction) are important.

Hardness of alumina is extremely high. It may reach 2200 HV.

Due to such high hardness Alumina ceramics have excellent wear resistance.

Wear resistance of Metals and particularly Polymers is much lower. However it may be considerably increased in composite materials with alumina particle reinforced phase.

Alumina particles dispersed throughout a relatively soft matrix (metal or polymer) not only increase the material hardness and strength but also improve its tribological behavior.

Wear resistance is not only tribological property enhanced in alumina particle reinforced composites.

In some cases coefficient of friction of the composite is lower than that of matrix material.

Additionally hard alumina particles in a metal matrix composite decrease the probability of seizure between the sliding counterparts due to the abrasive effect of the particles polishing the surface of the counterpart.

6.1 Metal matrix composites reinforced with alumina

The methods of fabrication of metal matrix composites reinforced with alumina:

- Stir Casting. In this method alumina particles or short fibers are mixed with a molten matrix metal by means of mechanical stirring.

- Squeeze Casting Infiltration. The method is using a movable mold part (ram) for applying pressure on the molten metal and forcing it to penetrate into a performed dispersed alumina phase, placed into the lower fixed mold part.

- Sintering of a powder of a matrix metal mixed with alumina in form of particles or short fibers.

- Spray co-deposition. This method uses Thermal spraying technique for atomizing molten matrix metal droplets of which are delivered to a substrate in a high velocity gas stream together with dispersed alumina particles supplied to the stream from a separate container.

Different metals are used as matrices for alumina reinforced metal matrix composites:

- Aluminum alloys have been widely used as matrix materials for fabrication of metal matrix composites reinforced with alumina particles or fibers.

Engine pistons, engine blocks and other automotive and aircraft parts operating under severe friction conditions are fabricated from alumina reinforced aluminum matrix composites.

Alumina particles dispersed in an aluminum alloy increase its wear resistance more effectively than hard silicon (Si) particles in eutectic and hypereutectic Al-Si alloys [19].

The disadvantages of alumina reinforced aluminum matrix composites are relatively high coefficient of friction and high wear rate of the counterpart.

Addition of dispersed particles of a solid lubricant (e.g., graphite together with the alumina particles/fibers (heterophase composite) allows to decrease the coefficient of friction and the wear rate of the both sliding parts.

The coefficient of friction of the aluminum alloy (Al12SiCuNiMg) matrix heterophase composite containing 25-wt% of particulate Al2O3 with the particle size of 50 μm (~0.002”) and 5-wt% of glass carbon particles is lower by 20% than that of the composite reinforced with 30% of alumina only [20].

- Copper matrix composites are widely used in sliding electrical contacts of welding electrodes, railway overhead current systems, transfer switches, homopolar machines and other electrical applications.

Alumina particle reinforced copper matrix composites have an increased wear resistance and better refractory properties than non-reinforced copper.

However it was shown in [21] that the wear rate decreases firstly and then increases with the increase of addition of Al2O3 in the range (wt.%) from 1 to 5, exhibiting a minimum at 2% addition of Al2O3 and a maximum relative wear-ability of 3.13 times as much as that of copper. Copper-alumina composite was prepared in this work by the method of coprecipitation using NH4HCO3 as precipitation and CuSO4+NH4Al(SO4)2 as maternal solution.

- Zinc alloy matrix composites reinforced with alumina particles have been studied since eighties.

The results of tribological investigations of composites with the matrix made of the ZA-27 (Zn68,Al28.5Cu2.5) alloy reinforced with Al2O3 particles of sizes 12 and 250 μm (~0.0005” and 0.01”) in quantities of 3.5 and 10 mass % are presented in [22]. The highest wear resistance in the tests without lubrication was exhibited by the composite material reinforced by the Al2O3 particles of size 250 μm (~0.01”) in the amount of 5 mass %.

6.2 Polymer matrix composites reinforced with alumina particles

Such polymers as Polytetrafluoroethylene (PTFE), High Density Polyethylene (HDPE), Polyethereetherketone (PEEK) are widely used in tribological applications.

The best tribological properties are provided by the polymeric solid lubricant Polytetrafluoroethylene (PTFE) with the coefficient of friction varying within the range 0.02 - 0.1.

However polymers are very soft and therefore their wear rate is high. The wear resistance may be considerably improved by addition of hard ceramic particles/fibers (e.g., alumina). Unfortunately the reinforced phase micrometer-sized particles and fibers dispersed in a polymer matrix cause increased wear of the counterface and lead to higher coefficient of friction due to rough mating surface and unstable transfer film.

Undesirable abrasive effect may be eliminated if nanosized hard alumina particles are used as the filler (reinforcing phase) dispersed in a polymer matrix.

Friction and wear behavior of PTFE filled with alumina nanoparticles was studied in [23]. A solid lubricant composite material was made by compression molding blended PTFE and 40 nm alumina particles. The wear resistance increased monotonically with increasing filler concentration from 0 to 20 mass %. The composite has wear resistance over 600x higher than the unfilled samples. Only slight increase of the coefficient of friction was observed.

Effect of the nanoparticles shape on the wear resistance of alumina-PTFE nanocomposites was investigated in [24]. It was found that the inclusion of irregular shaped filler particles considerably reduced the wear of PTFE, but also led to increased friction. The wear resistance of PTFE was increased 3000x with 1 wt.% filler.

Comparative investigation of the tribological properties of micrometer- and nanometer-Al2O3-Particle-Filled poly(phthalazine ether sulfone ketone) (PPESK) composites [25] proved that the lowest wear rate was obtained for the composite filled with 1 vol %-nanometer alumina particles.

Effect of lubrication on the tribological properties of nano-alumina reinforced Polyoxymethylene (POM) composites was studied in [26]. It was concluded that alumina nanoparticles were more effective in enhancing tribological properties of the POM composites under oil lubrication conditions.

High Density Polyethylene (HDPE) filled with particles of alumina and hydroxyapatite as biocompatible composite for bone replacement (e.g., Total Hip Joint Prosthesis) was proposed in [27]. The properties of the proposed biocomposite were compared to those of pure HDPE. The composite demonstrated higher wear resistance, hardness and modulus of elasticity (stiffness).

Polymer matrix composites filled with hard alumina particles are also used as coatings applied over the engine bearing surface. Polyamide-imide, Epoxy or Phenolics may be used as the matrix material. Solid lubricants such as Molybdenum disulfide, Graphite or Polytetrafluoroethylene (PTFE) are also added to the polymer matrix for reducing the coefficient of friction. 2-5% of alumina particles (or other hard particles like Silicon carbide, Silicon nitride or Silica) enhance the wear resistance of the coating.

to top

7. Alumina reinforced engine bearing materials

In order to impart Engine bearings higher fatigue strength and better wear resistance and seizure resistance (compatibility) their metal based overlays may be reinforced with dispersed alumina particles (0.5-2%) [28].

Metal matrix composite anti-friction coatings of engine bearings are fabricated by Electrolytic co-deposition from an electrolyte solution containing Al2O3 particles.

Polymer Matrix Composites filled with 2-5% of hard alumina particles are also used as coatings applied over the engine bearing surface.

The author of the present article studied the effect of reinforcing alumina particles on the seizure resistance of aluminum alloys.

The metal matrix composite was prepared by an addition of 2% vol. of alumina particles with the sizes 0.4-0.8 mil (10-20 µm) into aluminum-5% tin-1% manganese alloy. The Al5SnMn and Al5SnMn2Al2O3 samples were cast at a horizontal continuous casting machine controlling gravity segregation during Solidification of metallic systems.

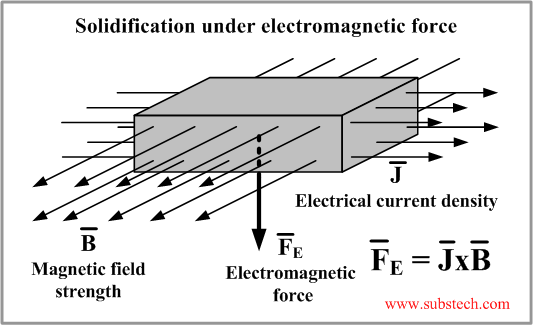

The technology is based on applying horizontally crossed electric and magnetic fields to the solidifying metal [29] (Fig.3).

Fig.3 Solidification under electromagnetic force

The method allows producing predetermined distribution of the second phase (alumina) in the matrix (aluminum) phase (bottom segregation, homogeneous distribution or top segregation).

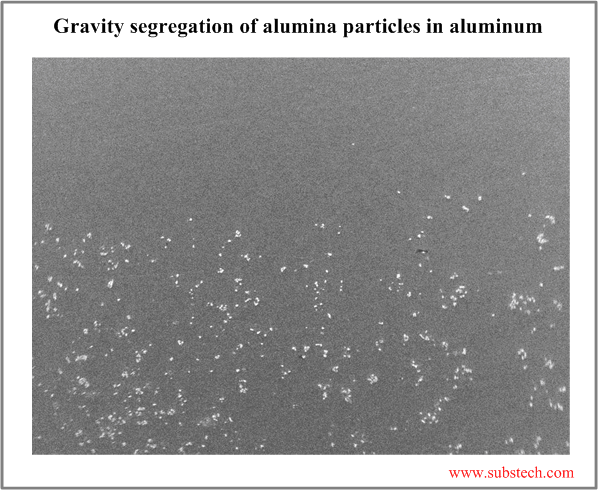

Due to the difference between the specific weights of liquid aluminum 143 lb/ft3 (2.3 g/cm3) and aluminum oxide 250 lb/ft3 (4.0 g/cm3) continuous casting without electromagnetic force results in a gravity segregation of alumina particles at the bottom part of the samples ( Fig.4).

Fig.4 Segregation of alumina particles in aluminum at the bottom of the sample (no electromagnetic force)

Electro-magnetic force applied to the solidifying material equalizes the apparent densities of aluminum and alumina.

No visible gradient of alumina particles concentration was observed on the specimens solidified under the action of the electromagnetic force.

The Fig.5 illustrates different behaviors of Al5SnMn and Al5SnMn2Al2O3 materials tested in the mixed regime of lubrication. The results are obtained from the Test Rig of King Engine Bearings Ltd.

Fig.5 Seizure test of engine bearings under oil starvation conditions

The tested bearings worked with insufficient oil supply provided by splash lubrication. The load applied to the bearing was increased every 30 min. by the increments of 1450 psi (10 MPa). The bearing back temperature was continuously recorded.

After the disconnection of the lubricant supplying pipe from the Al5SnMn bearing at the initial load 4350 psi( 30 MPa) the bearing temperature rose and stabilized at the level of 145°C (63°C) with a few peaks indicating pre-seizure conditions. Increase of the load to 5800 psi (40 MPa) has caused immediate seizure of the aluminum alloy with the journal material (steel) accompanied with a sharp temperature rise.

The behavior of the Al5SnMn2Al2O3 bearing was quite different. It demonstrated good anti-seizure properties. At the initial load 4350 psi (30 MPa) the bearing temperature stabilized at 131°F (55°C) and after each load increase the temperature rose by about 10°F and stabilized. Full seizure did not occur even at the high load of 11600 psi (80 MPa). Only at 13050 psi (90 MPa) the sliding materials (Al5SnMn2Al2O3 and steel) have seized.

Very good seizure resistance of Al5SnMn2Al2O3 alloy was achieved due to the presence of hard alumina particles, which have prevented seizure due to its polishing.

to top

8. Alumina ceramic for joint prostheses

Ceramics have been extensively used for hip replacement (total hip arthroplasty) and much rarer for knee replacement.

Fig.6 Hip prosthesis

Replacement of the femoral head material in a metal-on-polyethylene bearing from metal to alumina resulted in a reduction of polyethylene wear. However osteolysis caused by polyethylene debris generated by alumina-on-polyethylene prostheses was not prevented.

Alumina-on-alumina joint prostheses allowed to eliminate both metal and polyethylene debris formation.

The new generation alumina ceramics are manufactured by Hot Isostatic Pressing (HIP). They have a high density (248.4 lb/ft3 / 3.98 g/cm3), a high purity and fine grains (70 μinch / 1.8 μm) [30].

Fine Grain structure of alumina allows to achieve very low surface roughness after polishing (less than 2 μinch/0.05 μm Ra), which determines extremely low wear rate and low coefficient of friction.

Wear rate and coefficient of friction of different joint prosthesis materials

| Materials | Wear rate | Coefficient of friction | |

|---|---|---|---|

| mm/year | mil/year | ||

| Metal-on-polyethylene | 0.25 | 10 | 0.07 |

| Metal-on-Metal | 0.025 | 1 | 0.25 |

| Alumina-on-polyethylene | 0.075 | 3 | 0.002-0.07 |

| Alumina-on-alumina | 0.0025 | 0.1 | 0.002-0.07 |

Benefits of alumina-on-alumina hip prostheses:

- Low wear rate;

- High hardness (HV = 2200);

- High scratch resistance (low three body abrasive wear);

- Low coefficient of friction;

- Excellent surface finish;

- No ion dissolution;

- High strength

- High Fatigue strength;

- Good wetting by the synovial fluid;

- Biocompatibility.

The main disadvantage of alumina as a material for hip prostheses is its low fracture toughness and strength.

The fracture toughness and 4-point flexural strength of alumina were considerably improved due to high density, fine grain structure and use of Hot Isostatic Pressing.

4-point bending flexural strength of the new generation alumina has reached 91.4 ksi / 630 MPa).

Further improvement of the fracture toughness and flexure strength was made in alumina with additions of 17-20 vol.% of zirconia (ZrO2) and some other oxides (e.g., chromium oxide).

Zirconia toughened alumina (ZTA) has flexural strength 160 ksi (1100 MPa).

However alumina is still less suitable material for the artificial hips experiencing frequent impacts.

Another disadvantage of alumina-on-alumina hip prostheses is an audible “squeaking” of hip experienced by some patients during normal motion.

to top

9. Alumina ceramic bearings

Hybrid alumina bearings consist of ceramic balls (or rollers) and steel races, cages/retainers and seals/shields.

Hybrid ceramic bearings are mainly used in high speed and insulating applications.

Full alumina bearings are made only of ceramics (contain no steel parts).

Full ceramic bearings are widely used in harsh environments (chemicals, vacuum, high temperature, radiation).

Features of alumina ceramic bearings:

- Low weight (about 0.4 of steel bearings}.

- Exceptional corrosion resistance.

- High rotation speed and acceleration {centrifugal forces are low due to low weights of the balls/rollers and rings}.

- High thermal resistance. Maximum operating temperature is 1800°F (982°C).

- Excellent wear resistance.

- Long service life.

- Excellent insulating properties.

- High dimension stability (coefficient of thermal expansion is about 0.25 of steel).

- High hardness (about 1500 HV).

- High stiffness (resistance to elastic deformation) due to high modulus of elasticity.

- Non-magnetic.

- Low coefficient of friction due to good surface quality.

- Good Seizure resistance (compatibility) in vacuum.

- Greater accuracies.

Applications of ceramic bearings:

- Pumps for domestic hot water circulators, dishwashers and washing machines.

- Industrial pumps for pumping water from deep wells.

- Submersible pumps for aquariums and garden ponds.

- Automotive water pumps.

- Aircraft valves, transmissions and gearboxes.

- Gas turbine mainshaft.

- Dental handpiece turbines.

- Semiconductors processing equipment.

- Food processing equipment.

- High speed spindles.

- Electroplating equipment.

- Chemical processing equipment.

- Aircraft engines.

- Vacuum apparatus.

10. Ceramics in combustion engines

10.1 Benefits of alumina ceramics over metals

- Higher thermal efficiency

Maximum efficiency of a heat engine is:

ηmax = 1 - Tc/Th

where:

Tc - temperature of the cold sink (cooling media), K;

Th - temperature of the hot source (combustion chamber), K.

According to the expression higher combustion temperature results in better theoretical efficiency of the engine.

In addition to this higher temperature causes the fuel burning to be more complete, which also increases the engine efficiency.

Metal combustion chamber (cylinder) is capable to operate at max. 1000 K (1341ºF). If the chamber is made of a ceramic the operation temperature may be increased to 3000 K (4941ºF). Higher temperature in the combustion chamber improves the engine efficiency.

- Lower inertia forces

All combustion engines have accelerating parts (reciprocating or/and rotating).

A certain part of the combustion energy is consumed for driving these parts.

The inertia forces developed by the moving parts are proportional to their weights. Therefore decrease of the parts weights will increase the engine efficiency.

Alumina (as compared to metals) has a lower density and a higher specific strength.

Replacement of the materials of the moving parts from metals to alumina ceramic will result in higher engine efficiency.

- Better tribological properties

Alumina ceramics with fine grain structure may be polished to very high surface quality, which provides low coefficient of friction.

The main disadvantage of ceramics is low fracture toughness causing increased wear rate by the fracture mode of the abrasive wear when the material cracks in the subsurface regions surrounding the wear groove.

Toughened ceramics with homogeneous fine grain microstructure have low wear rate.

Depending on the operating temperature liquid lubricants, Solid lubricants or metallic overlays may be used for the lubrication of engine ceramic parts.

10.2 Current and potential applications of alumina in combustion engines

Current application of alumina in combustion engines:

- Reciprocating engines

- Valve guides

- Cam follower rollers

- Thermal barrier coatings (e.g., exhaust pipes)

- Turbocharger rotors

- Pump seals

- Spark plug insulators

- Turbine engines

- Nozzles

- Ceramic lining of combustors

- Turbine blades

Potential applications of alumina in combustion engines:

- Reciprocating engines

- Ceramic liners of combustion chambers

- Pistons

- Piston rings

- Cylinder heads

- Valves and valve guides

- Wankel engines

- Three-sides rotors

- Housing (combustion chamber)

- Side plates

- Turbine engines

- Rotors

- Exhaust components

- Vanes

- Shrouds

11. Summary

- The most important disadvantage of alumina ceramic limiting its use in tribological applications is insufficient fracture toughness, which results in an increased wear by micro-fracture mechanism.

- Toughening effect of zirconia added into an alumina matrix may be considerably increased in submicron and nanoscale alumina matrix composites.

- Presence of both toughening phase and solid lubricants dispersed in the alumina matrix results in a favorable combination of tribological properties of alumina composites: good wear resistance and low coefficient of friction.

- Nanoscale alumina composites reinforced with carbon nanotubes (CNT) combine good fracture toughness and low coefficient of friction due to the lubricating effect of CNT. Such materials present a great potential for tribological applications.

- Metal matrix composites and polymer matrix composites reinforced with alumina particles have increased wear resistance, higher strength, and improved seizure resistance.

- Addition of solid lubricants to an alumina reinforced composite results in lowering the coefficient of friction and further improvement of seizure resistance.

12. References

[1] Said Jahanmir, X. Dong, Wear mechanisms of aluminum oxide ceramics, Friction and wear of ceramics, 15-50 (1994).

[2 ] Tribology of ceramics, Report of the Committee on Tribology of Ceramics, National Academies, 1988, 110 pages.

[3] Yu and Kellett, Tribology of alumina-graphite composites, Ceramic engineering and Science proceedings, vol.17, No.3 , 1996, pp.220-230.

[4] Subhranshu Sekhar Samal and Smrutisikha Bal, Carbon Nanotube Reinforced Ceramic Matrix Composites- A Review, Journal of Minerals & Materials Characterization & Engineering, 2008, Vol. 7, No.4, pp 355-370.

[5] An, You and Lim, Tribological properties of hot-pressed alumina CNT composites, Volume 255, Number 1, August 2003 , pp. 677-681(5).

[6] Lim D.S., You D.H., Choi H.J., Lim S.H., Jang H., Effect of CNT distribution on tribological behavior of alumina-CNT composites, International Conference on Wear of Materials No15, San Diego, California , 2005, vol. 259, no 1, pp. 539-544.

[7] Ying Jin, Koji Kato and Noritsugu Umehara, Tribological properties of self-lubricating CMC/Al2O3 pairs at high temperature in air, Tribology Letters, Volume 4, Numbers 3-4, pp. 243-250.

[8] X.Ma and D.Xiao , Nanocomposite coatings of high lubricity and low friction fabricated by plasma spray processes, Surface modification technologies: proceedings of the 19th International Conference on Surface Modification Technologies, August 1-3, 2005, Minnesota, USA, pp. 150-155.

[9] Geoffrey Darut, Fadhel Ben-Ettouil, Alain Denoirjean, Ghislain Montavon, He´le`ne Ageorges, and Pierre Fauchais, Dry Sliding Behavior of Sub-Micrometer-Sized Suspension Plasma Sprayed Ceramic, Journal of Thermal Spray Technology, Volume 19(1-2) January 2010, pp. 275-285.

[10] V.V. Narulkar, S. Prakash, and K. Chandra, Effects of Temperature on Tribological Properties of Al2O3-TiO2 Coating, Defence Science Journal, Vol. 58, No. 4, July 2008 pp. 582-587.

[11] Xueqiang Cao, Development of New Thermal Barrier Coating Materials for Gas Turbines Oxide Coatings, Berichte des Forschungszentrums Jülich ; 4127

[12] G. Bolelli, L. Lusvarghi, T. Manfredini, F. Pighetti Mantini, E. Turunen, T. Varis, S-P. Hannula, Comparison between plasma- and HVOF-sprayed ceramic coatings.

Part II: tribological behaviour, International Journal of Surface Science and Engineering, Volume 1, Number 1/2007, pp. 62 – 79.

[13] Jih-Fen Lei, Advances in Thin Film Sensor Technologies for Engine Applications, NASA Technical Memorandum 107418.

[14] Christopher DellaCorte, James A. Fellenstein, Patricia A. Benoy, Evaluation of Advanced Solid Lubricant Coatings for Foil Air Bearings Operating at 25 and 500 °C, NASA/TM—1998-206619.

[15] Prengel, H G, Pfouts, W R, Santhanam, A T, Coating carbide cutting tools, Manufacturing Engineering, Jul 1996.

[16] Kamo, L., Greathouse, M., Kamo, R., Ceramic Slurry Coatings for Advanced Heat Engines, scientificcommons.org 1998.

[17] Paulina Neska-Bakus, Ireneusz Piwoński, Wear and friction behavior of alumina thin films prepared by sol-gel methods, Department of Chemical Technology and Environmental Protection, University of Lodz.

[18] Wladislaw Skoneczny, Jan Jurusik, Andrzej Burian, Investigations of the surface morphology of Al2O3 layers by atomic force microscopy, Materials Science-Poland, Vol. 22, No. 3, 2004, pp. 265-278.

[19] M.K. Surappa, S.V. Prasad and P.K. Rohatgi, Wear and abrasion of cast Al-Alumina particle composites, Wear, Volume 77, Issue 3, 15 April 1982, pp. 295-302.

[20] J. Myalski, J. Wieczorek*, A. Dolata-Grosz, Tribological properties of heterophase composites with an aluminium matrix, Journal of Achievements in Materials and Manufacturing Engineering, Volume 15 Issue 1-2 March-April 2006.

[21] Guanghong Zhou*, Hongyan Ding, Yue Zhang, David Hui, Aihui Liu, Fretting behavior of nano-Al2O3 reinforced copper matrix composites prepared by coprecipitation, MJoM Vol 15 (3) 2009 pp. 169-179.

[22] Miroslav Babić, Slobodan Mitrović, Ilija Bobić, ZA-27 alloy composites reinforced with Al2O3 particles, SERBIATRIB`07, 10th International Conference on Tribology.

[23] W. Gregory Sawyer, Kevin D. Freudenberg, Praveen Bhimaraj, Linda S. Schadler, A study on the friction and wear behavior of PTFE filled with alumina nanoparticles, Wear 254 (2003) pp. 573–580.

[24] David L. Burris, W. Gregory Sawyer, Improved wear resistance in alumina-PTFE nanocomposites with irregular shaped nanoparticles, Wear 260 (2006) pages 915–918.

[25] Xin Shao, Qunji Xue, Weimin Liu, Mouyong Teng, Honghua Liu, Xuquan Tao, Tribological behavior of Micrometer- and Nanometer-Al2O3-Particle-Filled poly(phthalazine ether sulfone ketone) copolymer composites used as frictional materials, Journal of applied polymer science, 2005, vol. 95, no5, pp. 993-1001.

[26] Sun Lanhui, Yang Zhenguo, Li Xiaohui, Tribological properties of nano-Al2O3 modified POM nanocomposites, Chinese Journal of materials Research, December 2007, vol.21, No.6, pp. 654-658.

[27] Shekhar Nath, Bikramjit Basu, Development of designed biocomposites for orthopedic applications.

[28] Dmitri Kopeliovich, Lead based engine bearing overlays, SubsTech (Substances&Technologies), august 2010.

[29] H. Branover, A. El-Boher, D. Kopeliovich, and A. Shapiro, Novel aluminum alloys for combustion engine slide bearings, Proceedings of the 28th Israel Conference on Mechanical Engineering, Beer Sheva, 14 - 15 June, 2000.

[30] Bernard Masson, The emergence of a new type of ceramics in total hip arthroplasty: the alumina matrix composite (AMC), Jounees Lyonnaises de la Hanche, 2008, pp.207-211.

to top