to Metals

to Metal properties and tests

Creep

Dr. Dmitri Kopeliovich

Creep is a phenomenon of slow plastic deformation (elongation) of a metal at high temperature under a constant load.

The creep mechanism:

At low stresses the creep is controlled by the diffusion of atoms through the grain boundaries. At higher stresses the creep strain proceeds due to the dislocations movement.

The rate of creep is a function of the material, the applied stress value, the temperature, and the time exposure.

Considerable creep deformation, causing damage of machines and structures occur at high temperatures (about a half of the melting point measured in the absolute temperature scale). Therefore this phenomenon is taken into account in design and operation of heat exchangers, steam boilers and pipes, jet engines and other loaded equipment, working at high temperatures.

Soft metals (lead, tin) may experience creep at room temperature.

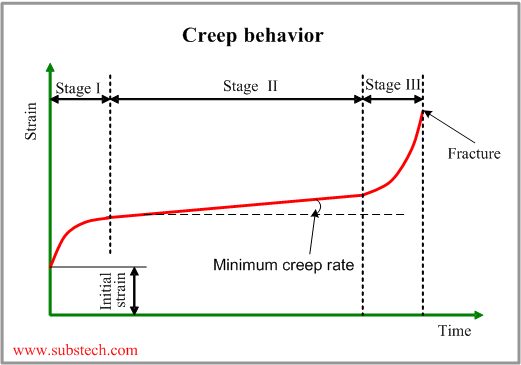

A typical creep behavior is presented in the diagram:

The initial strain is not time dependent and it is caused mainly by elastic deformation.

The first stage creep is characterized by relatively fast plastic deformation occurring at decreasing rate. During this stage resistance creep increases causing decrease the deformation rate.

The second stage creep occurs at a constant and relatively low deformation rate. This rate is used in the engineering design.

The rate of creep at the second stage depends on both the load (stress) and the temperature.

The third stage creep is associated with accelerated strain rate caused by decrease of the cross sectional area of the specimen (necking). This stage is finalized by the specimen fracture.

At room temperature creep is negligible at any stress below the yield point.

The quantity, which is used in precise design of machines and structures working at elevated temperatures, is creep strength.

Creep strength is a stress which causes a definite creep strain after a specified period of time at a given temperature.

Creep strength of a material is much lower, than its tensile strength.

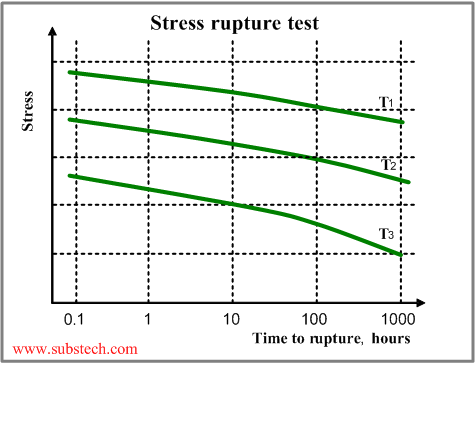

If a large amount of deformation is tolerated rupture strength is used in design.

Rupture strength is a stress which causes a fracture of a metal after a specified period of time at a given temperature.

Creep strength and rupture strength are determined in stress-rupture tests conducted in [Tensile test and Stress-Strain Diagram|tensile test]] machines equipped with a furnace providing uniform heating of the tested specimens.

This machine records amount of strain at every moment after the test has started and until the specimen failure.