to Polymers

to Methods of polymers fabrication

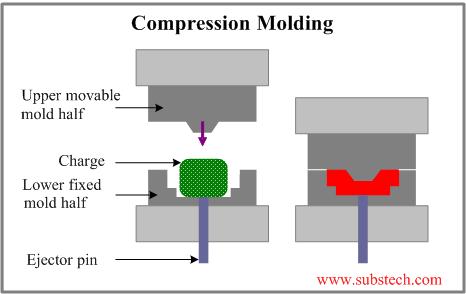

Compression molding of polymers

Dr. Dmitri Kopeliovich

Compression Molding is a process in which a molding polymer is squeezed into a preheated mold taking a shape of the mold cavity and performing curing due to heat and pressure applied to the material.

The method is used mostly for molding thermosetting resins (thermosets), but some thermoplastic parts may also be produced by Compression Molding.

The method uses a split mold mounted in a hydraulic press

Compression Molding process involves the following steps:

- A pre-weighed amount of a polymer mixed with additives and fillers (charge) is placed into the lower half of the mold.

The charge may be in form of powders, pellets, putty-like masses or pre-formed blanks.

The charge is usually preheated prior to placement into the mold. Preheated polymer becomes softer resulting in shortening the molding cycle time.

- The upper half of the mold moves downwards, pressing on the polymer charge and forcing it to fill the mold cavity.

The mold, equipped with a heating system, provides curing (cross-linking) of the polymer (if thermoset is processed).

- The mold is opened and the part is removed from it by means of the ejector pin.

If thermosetting resin is molded, the mold may be open in hot state – cured thermosets maintain their shape and dimensions even in hot state.

If thermoplastic is molded, the mold and the molded part are cooled down before opening.

Compression Molding cycle time is about 1-6 min, which is longer than Injection Molding cycle.

The method is suitable for molding large flat or moderately curved parts.

Materials commonly processed by Compression Molding are:

Compression Molding is used for manufacturing electrical wall receptacles, brush and mirror handles, meter cases, trays, circuit breakers, cookware knobs, clothes dryer blower fan blade, electronic and cooking utensils, milling machine adjustment wheel, automotive parts, water testing equipment buttons, television cabinets, dinnerware, appliance housings, radio cases, aircraft main power terminal housing, hoods, pot handles, spoilers, electric plugs and sockets, fenders, dinnerware plates, scoops.

to top