Main page

About us

Sliding Bearings Consulting

Advertising Opportunities

to Fluids

to Dispersions

Ultrasonic processing

Dr. Dmitri Kopeliovich

Acoustic waves of ultrasonic frequencies (16 kHz to 2 MHz) are used for materials processing .

Parameters of ultrasonic processing (amplitude, frequency, power) are well controlled.

Ultrasonic processing of Fluids employs the phenomenon of acoustic cavitation.

Acoustic cavitation is the formation of bubbles (cavities) in a liquid as a result of a rapid drop of the liquid pressure caused by a sound wave passing through the liquid.

Ultrasonic processing of solids utilizes the effect of the high frequency mechanical vibration producing friction and abrasion actions.

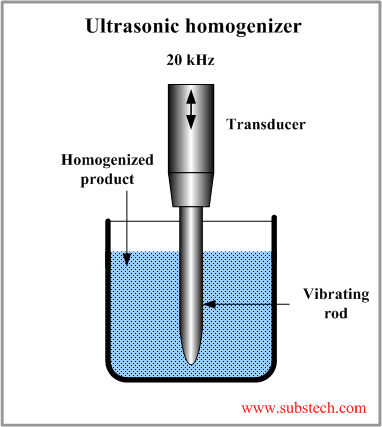

Ultrasonic homogenization

Ultrasonic Homogenization is a technique of dispersions processing, which utilizes ultrasonic waves for homogeneous distribution of the dispersed phase by the following actions: reducing the sizes of the dispersed particles/droplets (breaking); disintegrating the dispersed particles agglomerates; blending the dispersed phase in the liquid.

Ultrasonic Homogenization is a technique of dispersions processing, which utilizes ultrasonic waves for homogeneous distribution of the dispersed phase by the following actions: reducing the sizes of the dispersed particles/droplets (breaking); disintegrating the dispersed particles agglomerates; blending the dispersed phase in the liquid.

Ultrasonic homogenizing is a result of acoustic cavitation. The cavitation bubbles form at low pressure part of the of the wave cycle. When the pressure rises the cavities contract at high velocity. Such collapse creates a localized impact pressure (up to 20000 psi/1380 bar), which breaks the particles (or liquid globules in emulsions), disintegrate the particles agglomerates and produces high speed (up to ~600 mph/1000 km/h) turbulent streams blending the dispersed phase.

Ultrasonic homogenizing may be applied for processing of various volumes of liquids (resins, Paints, Adhesives, coatings, Lubricants, inks, food emulsions, etc.) in the range from 1 ml to 2000 l.

to top

Ultrasonic cleaning

Ultrasonic cleaning utilizes cavitation effect for removing contaminant particles from the workpiece immersed into a liquid media (water based or organic) processed with ultrasonic waves.

The high pressure wave formed as a result of collapse of the cavitation bubbles act on the dirt (contaminant) adhered to the workpiece surface. The dirt particles (dust, pigment, finger prints, polishing compounds, flux, oil, fat) dislodge from the surface.

In order to enhance the cleaning effect Surfactants (substances reducing the surface energy) may be added into the cleaning solution.

to top

Ultrasonic degassing

Ultrasonic degassing is the process of a purification from the gases dissolved in a liquid by means of ultrasonic processing. The molecules of the dissolved gasses diffuse into the cavitation bubbles formed by the ultrasound passing through the liquid. The bubbles flow up and transport the gases to the atmosphere.

Ultrasonic processing produce a great surface area of the bubbles due to their small sizes. This makes the ultrasonic degassing more effective than other degassing methods such as bubbling with an inert gas or vacuum treatment.

to top

Sonochemistry

Sonochemistry is the method of enhancing chemical reactions by means of ultrasonic processing.

The effect of ultrasonic processing is similar to the effect of a catalyst.

Ultrasound accelerates the chemical reaction kinetics:

- Shock waves created by the collapsing cavitation bubbles reduce the dispersed particle size and increase the dispersed phase surface area (dispersion and emulsification);

- Heat and mass transfers are accelerated by high speed turbulent streams formed by the cavitation;

- The reaction speed is increased by the local heating to about 5000K due to the cavitation;

- Energy of activation is reduced;

- The surface of the solid phase is cleaned from the contaminants and dirt.

One of the applications of sonochemistry is the catalytic transesterification for the production of biodiesel.

to top

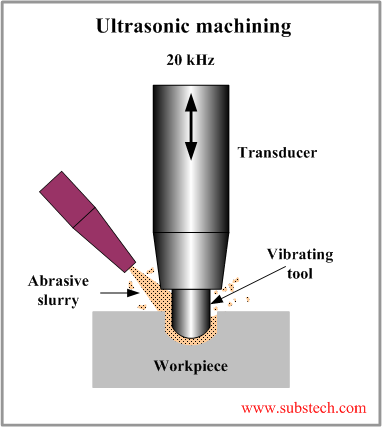

Ultrasonic machining

Ultasonic machining is a machining technique utilizing an abrasive slurry supplied to the space between the workpiece and a tool vibrating at an ultrasonic frequency.

Ultasonic machining is a machining technique utilizing an abrasive slurry supplied to the space between the workpiece and a tool vibrating at an ultrasonic frequency.

The material of the workpiece is removed by the following mechanisms:

- Hammering of the abrasive particles against the surface of the workpiece by the tool;

- Erosion of the workpiece surface bombarded by the abrasive particles accelerated by the shock waves of the cavitation;

- Local high pressure produced by the collapsing cavitation bubbles.

Typically the tool frequency is 20 kHz and the amplitude is in the range 0.0005-0.004” (0.013-0.1 mm).

The tool is moving down maintaining the gap between the surfaces of the workpiece and the tool.

The machined surface is free of burrs, residual stresses, distortions and chemical changes.

Very brittle materials (e.g. Ceramics, Tool and die steels, stones) may be machined with ultrasonic tools.

to top

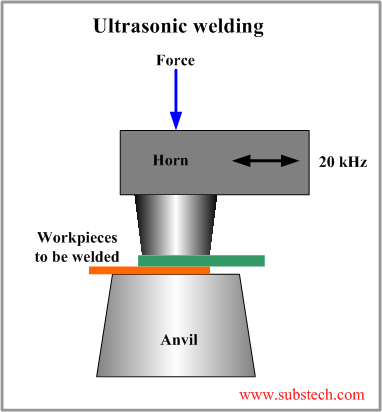

Ultrasonic welding

Ultrasonic Welding is a plastics welding process, in which two work pieces are bonded as a result of a pressure exerted to the welded parts combined with application of high frequency acoustic vibration (ultrasonic).

Ultrasonic Welding is a plastics welding process, in which two work pieces are bonded as a result of a pressure exerted to the welded parts combined with application of high frequency acoustic vibration (ultrasonic).

Ultrasonic vibration transmitted by a metal tool (horn, sonotrode) causes oscillating flexing of the material and friction between the parts, which results in a closer contact between the two surfaces with simultaneous local heating of the contact area. The plastic melts in the contact area, the polymer molecules are cross-linked, forming a strong joint.

Ultrasonic Welding cycle takes about 1 sec. The frequency of acoustic vibrations is in the range 20 to 70 kHz (commonly 20-40 kHz). The ampltude of the acoustic vibrations is about 0.002” (0.05 mm).

Thickness of the welded parts is limited by the power of the ultrasonic generator.

Ultrasonic Welding is used mainly for processing amorphous polymers (Polysterene (PS), Acrylonitrile-Butadiene-Styrene (ABS))

Applications of Ultrasonic Welding:

- Medical equipment (filters, face mask, valves, cardiometry reservoir);

- Automotive components (glove boxes doors, filters, valves, airflow sensors);

- Appliance (vacuum cleaner, steam iron, dishwasher components);

- Electrical equipment (switches, terminal blocks,connectors);

- Electronic and computer components;

- Toys.

Advantages of Ultrasonic Welding:

- Short welding cycle;

- Easily automated and controllable;

- Small amount of flash forms;

- Low energy consumption;

Disadvantages of Ultrasonic Welding:

- Only small and thin parts may be welded;

- Tool design is required.

Related internal links