Main page

About us

Sliding Bearings Consulting

Advertising Opportunities

SubsTech’s sister website Smooth Sliding provides independent engineering consulting services that help you to solve engine bearing related issues: failures, material selection, geometry design and optimization of hydrodynamic conditions.

Smooth Sliding is an engineering consulting company run by Dr. Dmitri Kopeliovich:

- VP R&D of King Engine Bearings.

- World leading expert (32 years of experience) in design, technology and materials for Engine bearings in applications such as automotive, renewable energy, aviation, racing and others.

- Founder and owner of SubsTech (Substances & Technologies) – a leading professional website on Materials Science and Engineering.

- Author of numerous scientific and engineering publications and patents.

- Founder and owner of Smooth Sliding.

For further information and for requesting consulting services please visit our sister website Smooth Sliding.

to Metals

to Engine bearings

Optimization of Clearance Design for High Performance Engine Bearings

Hydrodynamic lubrication

Engine bearings operate mostly in a hydrodynamic regime of lubrication, in which the bearing surface is separated from the journal surface by pressurized oil.

A loaded rotating journal is always displaced from the concentric position, forming a converging gap (wedge) between the bearing and the journal surfaces. The presence of this oil wedge is indispensable to the normal operation of a hydrodynamic bearing.

If the journal and the bearing are perfectly concentric, the wedge is not formed and the oil is not pressurized. A difference between the bearing and the journal diameters allows the journal to shift from the concentric position and form a wedge.

Thus the wedge parameters are determined by the difference between the diameters. This is called oil clearance (or bearing clearance). Clearance is the basic geometric parameter of engine bearings.

There is another way to create a converging gap (an oil wedge) – a bearing having a lemon shape due to the varying thickness of the bearing wall, having its maximal value at the centerline and gradually decreasing towards the parting line.

The difference between the maximum and minimum wall thickness (bearing eccentricity) is added to the eccentricity, that is caused by the displacement of the journal from the concentric position.

Such increased total eccentricity enables a more stable hydrodynamic regime.

With regards to the hydrodynamic conditions, a bearing with eccentricity is equivalent to a bearing with an increased diameter (or an increased oil clearance). The oil wedge of a bearing with eccentricity is the same as the wedge formed by a bearing with an increased diameter (”effective bearing diameter”). However, since the actual bearing diameter is not changed, the adverse effect of noise and vibration from excessive bearing clearance is prevented.

to top

What is the optimal clearance?

High performance engines operate mostly at a high rotation speed and produce increased loads that are applied to the bearings.

Both characteristics affect the hydrodynamic regime of lubrication.

Higher bearings loads result in a decrease of minimum oil film thickness. When its value drops below either the journal surface roughness or the value of the geometric distortions, the hydrodynamic lubrication changes to a mixed lubrication regime. This is characterized by metal-to-metal contact. In order to prevent or reduce metal-to-metal contact, the clearance should be designed to produce the maximum possible level of minimum oil film thickness.

Such clearance could be considered as optimal - unless the engine operation conditions (load, rotation speed) change in the same engine within a relatively wide range. Therefore the clearance value providing the maximum level of the minimum oil film thickness would change correspondingly.

Additionally sometimes the maximum value of minimum oil film thickness may be reached when the values of other hydrodynamic parameters such as oil temperature, oil leakage flow or oil pressure distribution become unacceptable.

All these factors should be taken into account in the design of optimal clearance.

to top

Calculations of optimal clearance

King Engine Bearings has developed a software that simulates engine bearing performance under various conditions. The software, called ENSIM™, is an advanced engine simulation module. It is capable of calculating the thermodynamic, dynamic, hydrodynamic and mechanical parameters of bearing operation.

ENSIM™ is used for designing new bearings and for modifying the bearings of existing engines.

For the purposes of this theme paper study, calculations of the parameters of hydrodynamic lubrication were made for high performance bearings working under the following conditions:

- Bearing diameter: 2”

- Bearing length: 1”

- Oil type: 5W50 synthetic

- Oil inlet temperature: 175 °F

- Eccentricity: e=0 and e=0.0004”

- Bearing loads: 5,100 psi and 12,000 psi

- Rotation speeds: 2000 RPM, 4500 RPM and 8000 RPM

The main objective of the calculations was to determine the optimal values of clearance for various operational conditions. Such optimal clearance should provide the maximum possible level of minimum oil film thickness.

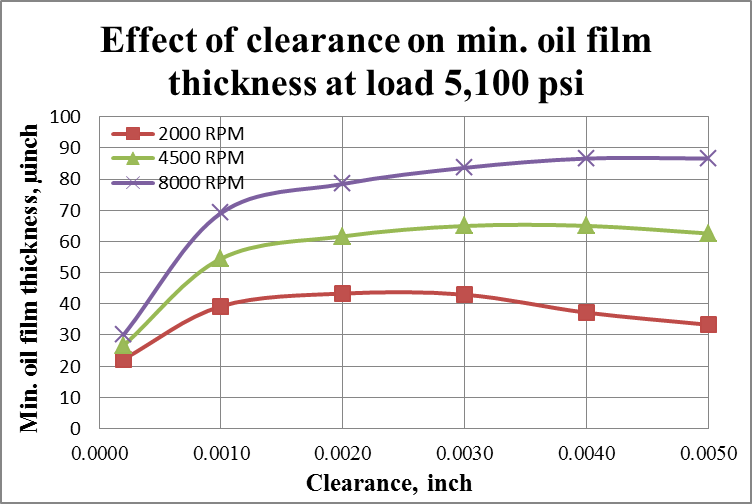

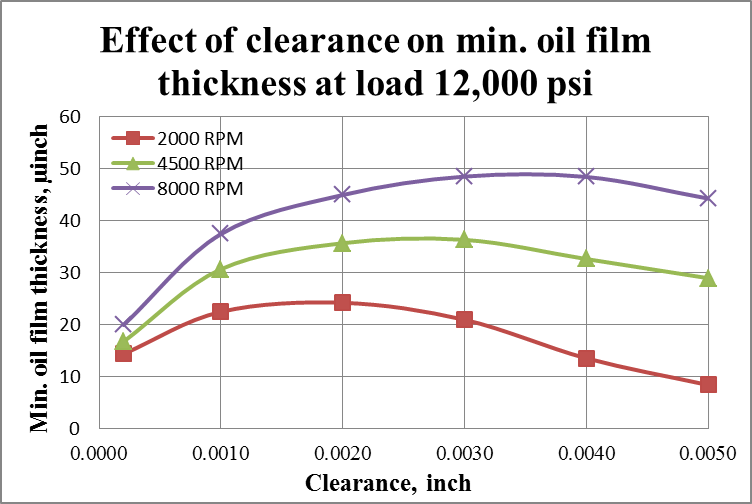

The results of the calculations of the effect of clearance on min. oil film thickness are presented in Fig.1 and 2.

Fig.1

Fig.2

It is seen in the graphs that min. oil film thickness has maximum values which are different at different loads and rotation speeds.

When the clearance increases from low values, the resulting value of min. oil film thickness also increases. This is due to the formation of a larger supporting oil wedge, which is mandatory for stable hydrodynamic lubrication.

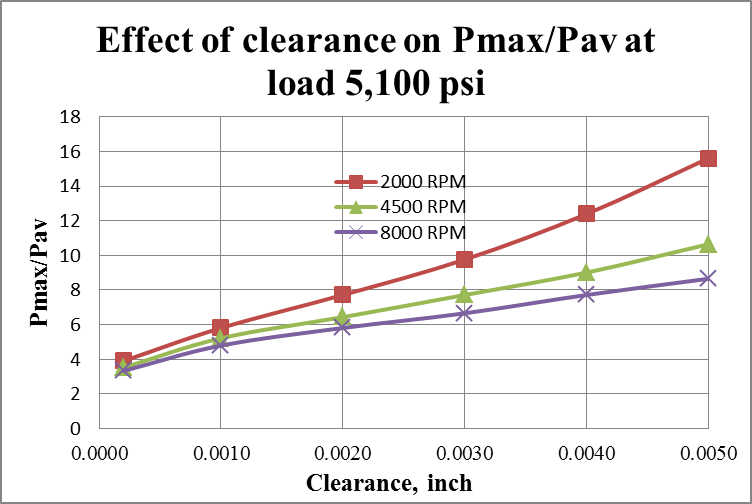

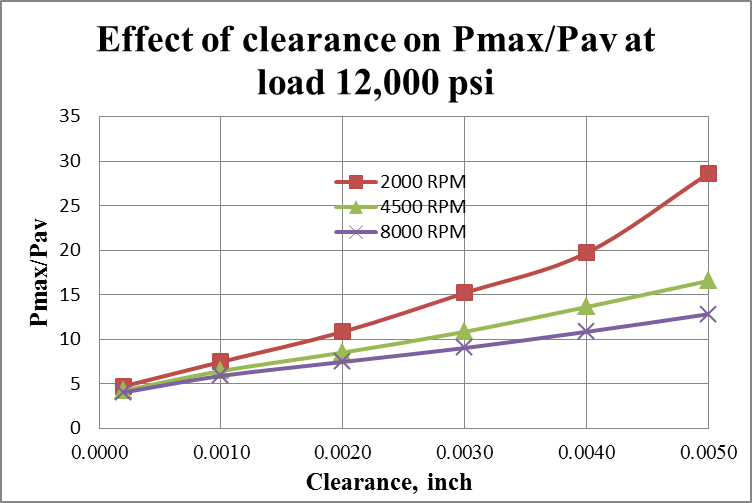

However, a further increase of clearance leads to a decrease of min. oil film thickness. This effect is caused by a localization of the oil pressure to a smaller area of the bearing surface. The non-homogeneity of the oil pressure distribution is characterized by the ratio Pmax/Pav.

Where:

Pav – the average load applied to the bearing surface (5,100 psi or 12,000 psi in our calculations)

Pmax – the peak value of the oil pressure

An example of the oil pressure distribution is shown in Fig.3.

Fig.3

Besides a decrease of min. oil film thickness, the non-homogeneous oil pressure distribution caused by excessive clearance may result in fatigue of the bearing material in the area of peak pressure. This phenomenon is known as knocking.

The effect of clearance on the oil pressure distribution is presented in Fig. 4 and 5.

Fig.4

Fig.5

As seen in the graphs, clearance exceeding 0.003” may results in substantial non-homogeneity of the oil pressure distribution.

Another effect of large clearance is increased oil leakage out of the bearing. Oil leakage has an important positive role – it removes the heat generated by the bearing thus preventing overheating of the oil.

However, too large a flow of oil leakage may cause a drop of oil pressure and even oil starvation, which terminates hydrodynamic lubrication.

Oil leakage from thea bearing with excessive clearance may be reduced by changing to a higher viscosity.

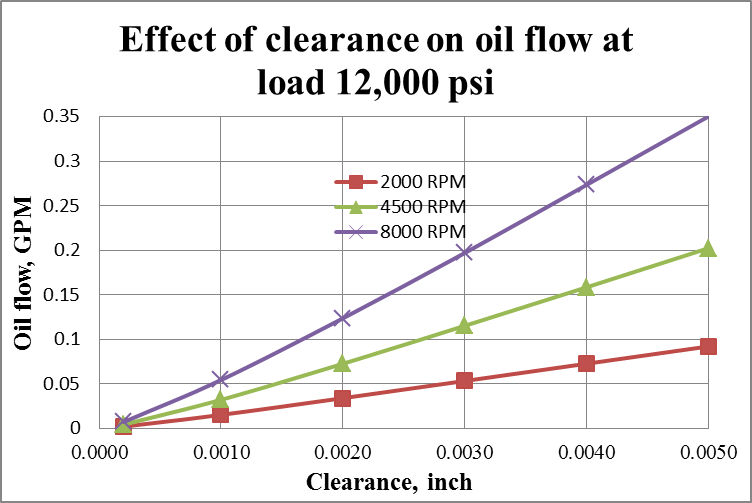

The influence of clearance on oil flow is seen in Fig.6.

Fig.6

Now consider the effect of tight clearances on the hydrodynamic parameters.

The advantages of small clearances are: low values of oil peak pressure and low oil leakage.

However there are clear drawbacks.

First of all, min. oil film thickness at tight clearances may be too low (Fig.1 and 2).

The second adverse factor is related to possible distortions of the bearing housing and crankshaft in high performance engines working at high loads and high rotation speeds. The distortions are much more dangerous in bearings with small clearances.

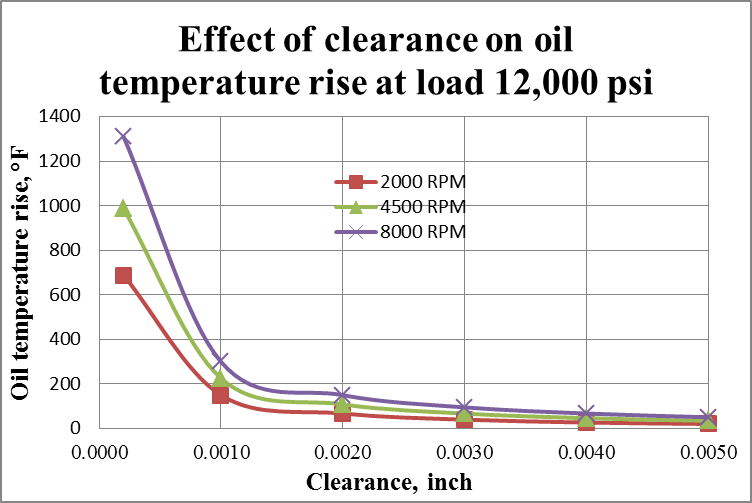

The third disadvantage of tight clearances is excessive heating of the oil. The friction energy generated by the bearing at high rotation speeds may heat the oil to a temperature above its maximum temperature limit (e.g. 500 °F for synthetic oil). The graphs in Fig. 7 illustrates the effect of clearance on oil temperature rise (delta T).

Fig.7

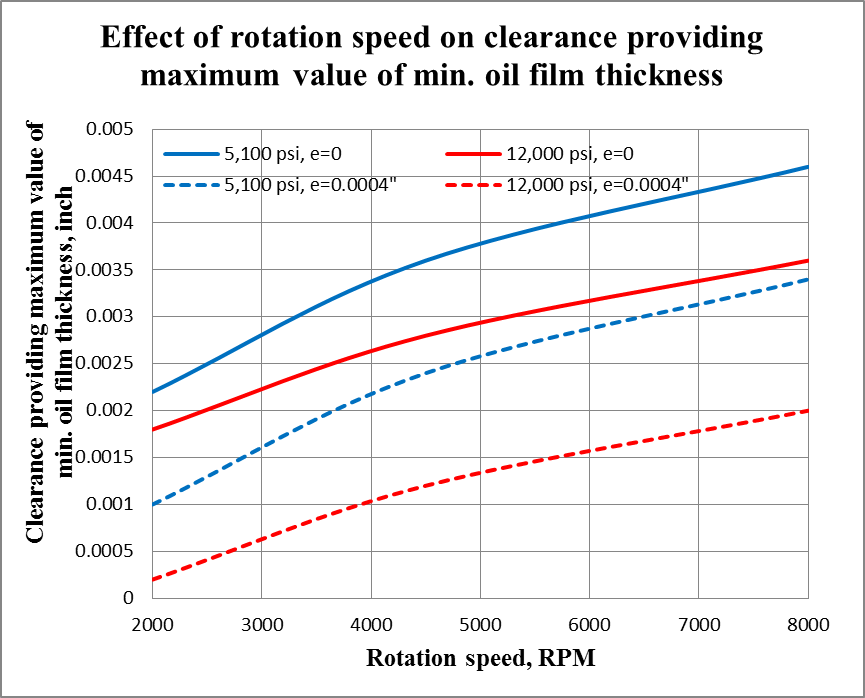

As was noted in p.1, clearance is not the only bearing parameter determining the value of min. oil film thickness. The effect of bearing eccentricity is very similar to that of clearance. The value of eccentricity is taken into account in hydrodynamic calculations. Fig.8 presents the results of calculations of clearances providing the maximum values of min. oil film thickness for different eccentricities (e=0 and e=0.0004”).

Fig.8

An increase of bearing eccentricity shifts the optimal clearance to lower values. This reduces the likelihood of knocking and localized overloading. However the real situation is more complicated than the theoretical calculations. As a matter of fact, the actual eccentricity of high performance bearings during their operation is lower than the difference between the maximum and minimum wall thickness. The eccentricity is reduced by distortions of the bearing housing due to high loads and high rotation speeds. Using King’s ENSIM™ software we are able to determine the optimal eccentricity value for a specific performance requirement. This optimal value in our XP and HP race series is called EccentriX™.

to top

Conclusions and recommendation

- There is a value of clearance at which minimum oil film thickness reaches the maximum value.

- Loose clearance results in lower temperature rise but in greater oil leakage (risk of oil starvation) and in higher oil pressure peak (risk of material fatigue).

- Tight clearance results in small oil leakage, low oil pressure peak but in greater oil temperature rise and in greater sensitivity to geometric distortions of the housing and the crankshaft.

- The value of clearance required for formation of the maximum value of minimum oil film thickness is lower in bearings having greater eccentricity.

- The optimal range of clearance is 0.0015-0.003” (for a bearing with 2” diameter). Looser clearances are more suitable for highly loaded engines working at high rotation speeds and with thicker oils. Tighter clearances provide a better combination of hydrodynamic parameters in less loaded engines working at lower rotation speeds and using thinner oils.

Related internal links

to Metals

to Engine bearings