Main page

About us

Sliding Bearings Consulting

Advertising Opportunities

to Metals

to Metal joining technologies (welding, brazing, soldering)

Carbon Arc Welding

Dr. Dmitri Kopeliovich

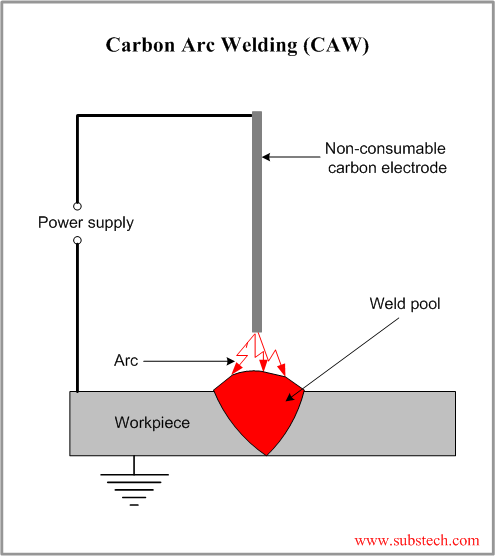

Carbon Arc Welding (CAW) is a welding process, in which heat is generated by an electric arc struck between an carbon electrode and the work piece. The arc heats and melts the work pieces edges, forming a joint.

Carbon arc welding is the oldest welding process.

If required, filler rod may be used in Carbon Arc Welding. End of the rod is held in the arc zone. The molten rod material is supplied to the weld pool.

Shields (neutral gas, flux) may be used for weld pool protection depending on type of welded metal.

Advantages of Carbon Arc Welding:

- Low cost of equipment and welding operation;

- High level of operator skill is not required;

- The process is easily automated;

- Low distortion of work piece.

Disadvantages of Carbon Arc Welding:

- Unstable quality of the weld (porosity);

- Carbon of electrode contaminates weld material with carbides.

Carbon Arc Welding has been replaced by Tungsten Inert Gas Arc Welding (TIG, GTAW) in many applications.

Modification of Carbone Arc Welding is Twin Carbon Electrode Arc Welding, utilizing arc struck between two carbon electrodes.

Work piece is not a part of welding electric circuit in Twin Carbon Electrode Arc Welding, therefore the welding torch may be moved from one work piece to other without extinguishing the arc.

to top

Related internal links