to Metals

to Metal forming technologies

Burnishing

Dr. Dmitri Kopeliovich

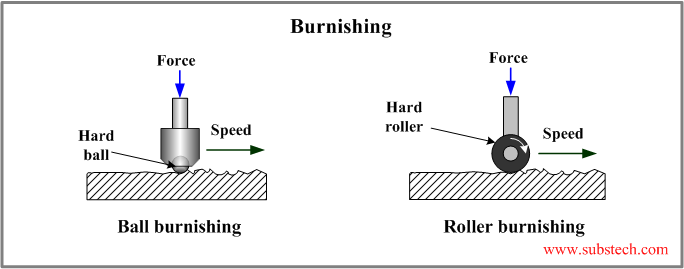

Burnishing is a cold working process in which the surface layer of a work piece is plastically deformed by a hard tool: either roller or sliding ball.

Benefits of burnishing

The surface of a machined part has a profile composed of alternating irregular micro-asperities (peaks)and micro-valleys. The roughness level of the surface is commonly characterized by the average deviation of the profile peaks and valleys from the mean line which is called Ra.

When a burnishing tool (ball or roller) is pressed into the surface it forces the material of the peaks to flow to the valleys and fill them. As a result the surface finish is improved: the Ra value may be decreased from 100 µin (2.5 µm) to 4 µin (0.1 µm).

However smothening is not the only result of burnishing operation. The material of the surface layer exerts Plastic deformation which produces a compressively stressed hardened skin.

The residual compressive stresses inhibit initiation and propagation of fatigue cracks resulting in an increase of the fatigue strength. The surface hardness of Steels and cast irons may be increased by twice; Aluminum alloys - by 20%.

The combination of the improved surfrace finish with the hardened skin provides a significant increase in the wear resistance of the material.

Other benefits of burnishing:

- Simple and highly productive operation which may be carried out in conventional machines (e.g. lathe).

- May replace more complicated operations such as honning, lapping, grinding.

- Requires low energy and torque since the pressure load is relatively low: commonly 10-100 lbf (4.5-45 kgf).

- Does not produce chips, shavings, filings, turnings or dust.

- Provides tight dimensional tolerances.

- Burnishing tools wear slowly.

Applications of burnishing

- Shafts (steel);

- Press rods (steel);

- Actuators (steel);

- Connecting rods (steel);

- Valve guides (bronze, steel);

- Bushes (bronze);

- Rocker arm (steel);

- Bearing housing (steel);

- Parts of plastic injection molds (steels);

- Aircraft fittings (Aluminum alloys);

- Truck wheels (aluminum alloys);

- Brake discs (aluminum alloys);

- Hinge pins (aluminum alloys);

- Hydraulic pistons (aluminum alloys);

- Pneumatic cylinders (aluminum alloys).