Main page

About us

Sliding Bearings Consulting

Advertising Opportunities

to Metals

to Foundry technologies

Squeeze casting

Dr. Dmitri Kopeliovich

Squeeze casting is a method combining casting and forging technologies.

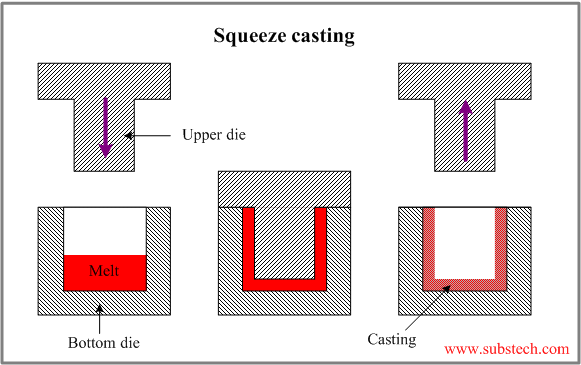

In contrast to other casting techniques (sand casting, die casting), in which a molten metal is poured (injected) into the mold cavity after the two parts ofthe mold are assembled, squeeze casting mold is closed after a portion of molten metal has been poured into the preheated bottom die.

The upper die lowers towards the bottom die causing the melt to fill the mold cavity.

The squeezing pressure is applied until full solidification of the casting.

A scheme of the process is shown in the picture:

Squeeze castings are characterized by:

- low shrinkage and gas porosity;

- enhanced mechanical properties because of fine grain structure caused by rapid solidification ;

- good surface quality.

Squeeze casting is commonly used for processing aluminum and magnesium alloys.

This process is also used for fabrication of reinforced metal matrix composites where molten aluminum infiltrates a fiber reinforcing structure.

to top

Related internal links

to Metals

to Foundry technologies