Main page

About us

Sliding Bearings Consulting

Advertising Opportunities

to Ceramics

to Ceramic properties and tests

Flexural strength tests of ceramics

Dr. Dmitri Kopeliovich

Extremely low ductility of ceramic materials does not allow measuring their mechanical properties by conventional tensile test, which is widely used for metals.

Brittle Materials, including ceramics, are tested by Flexure Test (Transverse Beam Test, Bending Test).

There are two standard Flexure Test methods:

3-point Flexure Test

In this test a specimen with round, rectangular or flat cross-section is placed on two parallel supporting pins. The loading force is applied in the middle by means loading pin.

The supporting and loading pins are mounted in a way, allowing their free rotation about:

- axis parallel to the pin axis;

- axis parallel to the specimen axis.

This configuration provides uniform loading of the specimen and prevents friction between the specimen and the supporting pins.

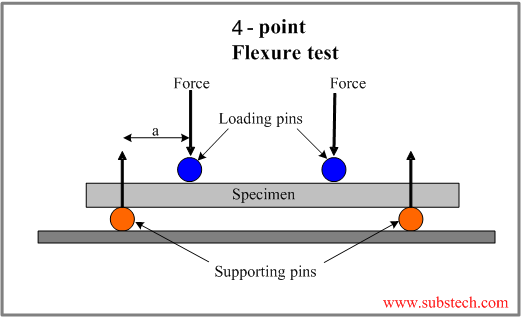

4-point Flexure Test

In this test the loading force is applied by means of two loading pins with a distance between them equal to a half of the distance between the supporting pins.

Flexural strength calculation

As a result of the loading, the specimen bends, causing formation of in its convex side and compression stress in the concave side.

The cross head speed in flexural test normally varies within the range 0.004-0.4 inch/min (0.1-10 mm/min). Speeds 1 mm/min and 0.1 “/min (2.54 mm/min) are mostly used in the tests.

The maximum stress and corresponding maximum strain are calculated for every load value.

The results are then plotted in the stress-strain diagram.

Modulus of Rupture (Flexural Strength) is the stress of the extreme fiber of a specimen at its failure in the Flexure Test.

Flexural Strength is calculated by the formula:

σ = 3LF/(2bd²) in 3-point test of rectangular specimen

σ = 3Fa/(bd²) in 4-point test of rectangular specimen

σ = 16Fa/(πD³) = 2Fa/(πr³) in 4-point test of round specimen

Where

L – specimen length;

F – total force applied to the specimen by two loading pins;

b – specimen width;

d – specimen thickness;

r – specimen section radius;

a - distance between the supporting and loading pins;

D – section diameter of round specimen.

to top

Related internal links