Main page

About us

Sliding Bearings Consulting

Advertising Opportunities

to Composites

to Polymer Matrix Composites

Closed mold fabrication of Polymer Matrix Composites

Dr. Dmitri Kopeliovich

Closed Mold methods are used when mass production of identical parts with both smooth surfaces is required.

Closed Molding methods are used for fabrication of Fiberglasses, Carbon Fiber Reinforced Polymer Composites and Kevlar (aramid) fiber reinforced polymers.

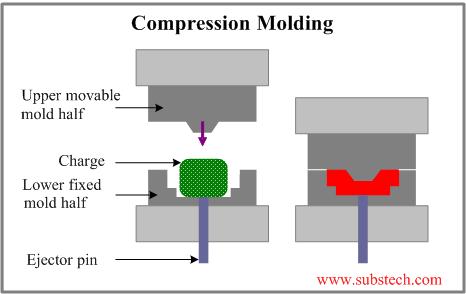

Compression Molding

Compression Molding is a Closed Mold process in which a molding charge is squeezed into a preheated mold taking a shape of the mold cavity and performing curing (cross-linking) due to heat and pressure applied to the material.

The method uses a split mold mounted in a hydraulic press

Compression Molding process involves the following steps:

- A pre-weighed amount of a polymer (commonly thermosetting resin) mixed with chopped reinforcing fibers, hardening agent, anti-adhesive agent and pigment (charge) is placed into the lower half of the mold.

The charge may be in form of powders, pellets, putty-like masses or pre-formed sheets.

The charge is usually preheated prior to placement into the mold. Preheated polymer becomes softer resulting in shortening the molding cycle time.

- The upper half of the mold moves downwards, pressing on the charge and forcing it to fill the mold cavity.

The mold, equipped with a heating system, provides curing (cross-linking) of the polymer matrix (if thermosetting resin is processed).

- The mold is opened and the part is removed from it by means of the ejector pin.

Compression Molding cycle time is about 1-6 min, which is longer than Injection Molding cycle.

The method is suitable for mass production of flat or moderately curved parts.

to top

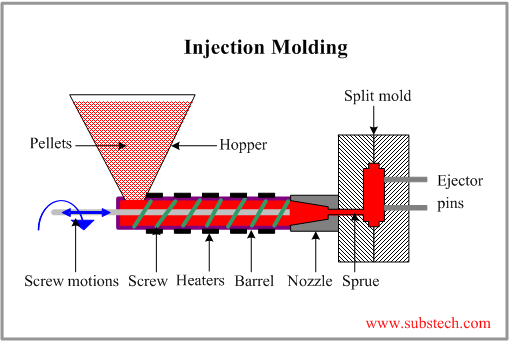

Injection Molding

Injection Molding is a Closed Mold process in which molten polymer (commonly thermoplastic) mixed with very short reinforcing fibers (10-40%) is forced under high pressure into a mold cavity through an opening (sprue).

Polymer-fiber mixture in form of pellets is fed into an Injection Molding machine through a hopper. The material is then conveyed forward by a feeding screw and forced into a split mold, filling its cavity through a feeding system with sprue gate and runners.

Screw of injection molding machine is called reciprocating screw since it not only rotates but also moves forward and backward according to the steps of the molding cycle.

It acts as a ram in the filling step when the molten polymer-fibers mixture is injected into the mold and then it retracts backward in the molding step.

Heating elements, placed over the barrel, soften and melt the polymer.

The mold is equipped with a cooling system providing controlled cooling and solidification of the material.

The polymer is held in the mold until solidification and then the mold opens and the part is removed from the mold by ejector pins.

Injection Molding is used mainly for thermoplastic matrices, but thermosetting matrices are also may be extruded. In this case curing (cross-linking) occurs during heating and melting of the material in the heated barrel.

A principal scheme of an Injection Molding Machine is shown in the picture.

Injection Molding is highly productive method providing high accuracy and control of shape of the manufactured parts. The method is profitable in mass production of large number of identical parts.

One of the disadvantages of the method is limited length of fibers decreasing their reinforcing effect.

to top

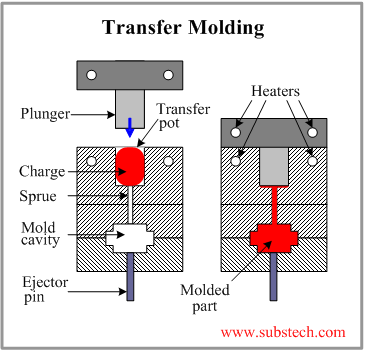

Transfer Molding

Transfer Molding (Resin Transfer Molding) is a Closed Mold process in which a pre-weighed amount of a polymer is preheated in a separate chamber (transfer pot) and then forced into a preheated mold filled with a reinforcing fibers, taking a shape of the mold cavity, impregnating the fibers and performing curing due to heat and pressure applied to the material.

The method is used primarily for molding Polymer Composites with thermosetting resin matrices, but some thermoplastic parts may also be produced by Transfer Molding.

The picture below illustrates the Transfer Molding Process.

The method uses a split mold and a third plate equipped with a plunger mounted in a hydraulic press.

The method combines features of both Compression Molding - hydraulic pressing, the same molding materials (thermosets) and Injection Molding – ram (plunger), filling the mold through a sprue.

Transfer Molding process involves the following steps:

- The mold cavity is filled with preformed reinforcing fibers.

- A pre-weighed amount of a polymer mixed with additives and fillers (charge) is placed into the transfer pot.

The charge may be in form of powders, pellets, putty-like masses or pre-formed blanks.

The charge is heated in the pot where the polymer softens.

- The plunger, mounted on the top plate, moves downwards, pressing on the polymer charge and forcing it to fill the mold cavity through the sprue and impregnate the fibers.

The mold, equipped with a heating system, provides curing (cross-linking) of the polymer (if thermoset is processed).

- The mold is opened and the part is removed from it by means of the ejector pin.

If thermosetting resin is molded, the mold may be open in hot state – cured thermosets maintain their shape and dimensions even in hot state.

If thermoplastic is molded, the mold and the molded part are cooled down before opening.

- The scrap left on the pot bottom (cull), in the sprue and in the channels is removed. Scrap of thermosetting polymers is not recyclable.

Transfer Molding cycle time is shorter than Compression Molding cycle but longer than Injection Molding cycle.

The method is capable to produce very large parts (car body shell), more complicated than Compression Molding, but not as complicated as Injection Molding.

to top

Related internal links