to Metals

to Metal joining technologies (welding, brazing, soldering)

Tungsten Inert Gas Arc Welding (TIG, GTAW)

Dr. Dmitri Kopeliovich

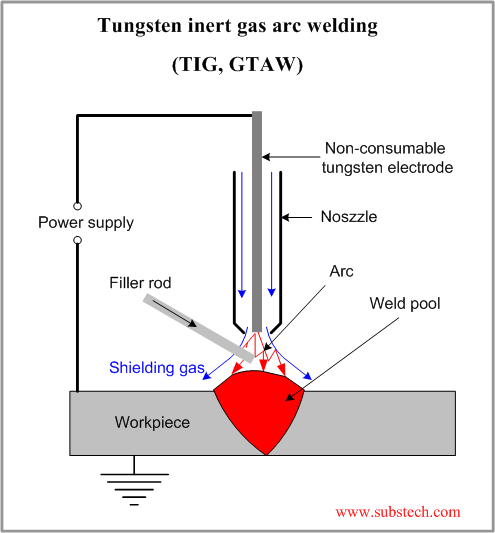

Tungsten Inert Gas Arc Welding (Gas Tungsten Arc Welding) is a welding process, in which heat is generated by an electric arc struck between a tungsten non-consumable electrode and the work piece.

The weld pool is shielded by an inert gas (Argon, helium, Nitrogen) protecting the molten metal from atmospheric contamination.

The heat produced by the arc melts the work pieces edges and joins them. Filler rod may be used, if required.

Tungsten Inert Gas Arc Welding produces a high quality weld of most of metals. Flux is not used in the process.

Advantages of Tungsten Inert Gas Arc Welding (TIG, GTAW):

- Weld composition is close to that of the parent metal;

- High quality weld structure

- Slag removal is not required (no slag);

- Thermal distortions of work pieces are minimal due to concentration of heat in small zone.

Disadvantages of Tungsten Inert Gas Arc Welding (TIG, GTAW):

- Low welding rate;

- Relatively expensive;

- Requres high level of operators skill.