SubsTech’s sister website Smooth Sliding provides independent engineering consulting services that help you to solve engine bearing related issues: failures, material selection, geometry design and optimization of hydrodynamic conditions.

Smooth Sliding is an engineering consulting company run by Dr. Dmitri Kopeliovich:

- VP R&D of King Engine Bearings.

- World leading expert (32 years of experience) in design, technology and materials for Engine bearings in applications such as automotive, renewable energy, aviation, racing and others.

- Founder and owner of SubsTech (Substances & Technologies) – a leading professional website on Materials Science and Engineering.

- Author of numerous scientific and engineering publications and patents.

- Founder and owner of Smooth Sliding.

For further information and for requesting consulting services please visit our sister website Smooth Sliding.

to Metals

to Engine bearings

Sputter bearing overlays

Dr. Dmitri Kopeliovich

Sputter overlays are deposited by Sputtering method (Physical Vapor Deposition (PVD)).

Sputtering utilizes argon ions for bombarding a cathodically connected target, made of the coating material (normally Al20Sn or Al40Sn).

Sputtering process:

- Evacuation of the vacuum chamber and introduction of argon gas.

- Heating of argon, which converts to plasma state: positively charged of argon ions form).

- Etching and activation of the substrate (bearing) surface. At this stage the bearings are cathodes and the positive argon ions bombard the substrate surface and clean it. Etching and activation stage provides good adhesion of the deposit to the bearing surface.

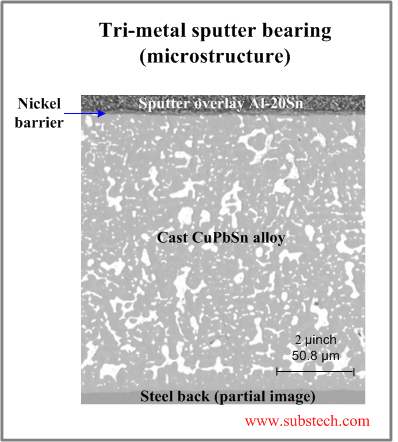

- Ni or NiCr diffusion layer is deposited. The cathode now is a target made of Ni/NiCr. The argon ions bombard the target knocking the atoms of nickel (nickel and chromium) out from the target. The atoms moving off the target meet the substrate surface and stick to it. Thickness of the diffusion layer is 0.00004”-0.00008” (1-2 µm).

- Deposition of the overlay (Al20Sn or Al40Sn). At this stage the cathode is a target made of aluminum-tin alloy (Al20Sn or Al40Sn). Atoms of the target are knocked out by the high energy ions and deposit on the substrate surface forming AlSn overlay.

Sputtering method provide extremely homogeneous distribution of tin within aluminum matrix. Hardness of aluminum-tin sputter material is about 90 HV, which is three times higher than hardness of aluminum-tin alloy prepared by conventional methods (casting).

Cast copper based bearings or high strength aluminum based bearings are commonly plated by sputter overlays.

Load carrying capacity of sputter bearings is highest of all bearing materials: 14500-17400 psi (100-120 MPa).

The disadvantages of sputter bearings: high production cost (slow deposition process) and poor soft anti-friction properties (compatibility, conformability, embedability).

Improvement of anti-friction properties and cost reduction are achieved by a combination of a sputter bearing shell in the high load position (conrod) with a common tri-metal bearing shell in the less loaded position (cap).

Sputter bearings are mainly used as connecting rod bearings in highly loaded diesel engines with direct fuel injection system.

to top

Related internal links

to Metals

to Engine bearings