to Metals

to Powder metallurgy

Sintering of metals

Dr. Dmitri Kopeliovich

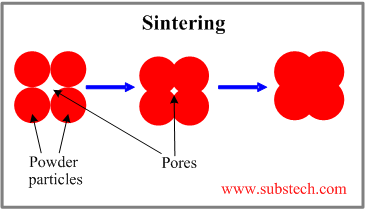

Sintering is a method involving consolidation of powder grains by heating the “green” compact part to a high temperature below the melting point, when the material of the separate particles diffuse to the neighboring powder particles.

During the diffusion process the pores, taking place in the “green compact”, diminish or even close up, resulting in densification of the part, improvement of its mechanical properties.

Decrease of the porosity, caused by the sintering process, is determined by the level of the initial porosity of the “green” compact, sintering temperature and time.

Sintering is enhanced if a liquid phase takes part in the process. This occurs when the powder contains a component, having the melting point lower, than the melting point of the base metal (for example in copper-lead-tin bearing alloys).

Continuous belt furnaces are commonly used for the sintering process.

In this machine a mesh belt conveyor moves the parts through a long tube like furnace.

Typical sintering furnace has three zones:

- Preheating zone for removing lubricant and other organic materials;

- Sintering zone, where the diffusion occurs;

- Cooling zone, where the sintered parts cool down.

Sintering process may be conducted in different atmospheres: air, inert atmosphere, reducing atmosphere (containing Hydrogen or carbon monoxide) or in vacuum.

Sintering occurs simultaneously with pressing in the hot pressing processes (hot isostatic pressing, hot die pressing).

All commercially used metals may be sintered.

to top

Related internal links

to Metals

to Powder metallurgy