to Metals

to Basic processes in metals

Plastic deformation

Dr. Dmitri Kopeliovich

Plastic deformation is a change of the material dimensions remaining after removal of the load caused the deformation.

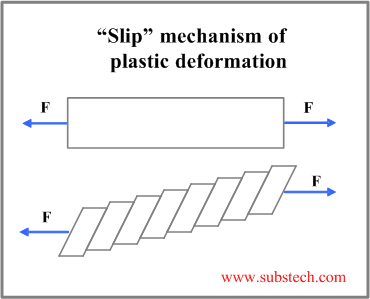

Plastic deformations in metals occurs by “slip” mechanism, illustrated in the picture:

When the yield stress is achieved one plane of atoms in crystal lattice glides over another. Few parallel slip planes form a block, neighboring with another block. Thus movement of the crystal planes is resulted in a series of steps, forming slip bands – black lines viewed under optical microscope.

Slip occurs when the share resolved stress along the gliding planes reaches a critical value. This critical resolved shear stress is a characteristic of the material.

Certain metals (Zn and Sn) deform by a process of twinning, differing from the normal slip mechanism, where all atoms in a block move the same distance. In the deformation by twinning atoms of each slip plane in a block move different distance, causing half of the crystal lattice to become a mirror image of another half.

In polycrystalline material directions of slips are different in different crystals. If a grain is oriented unfavorably to the stress direction its deformation is impeded. In addition to this grain boundaries are obstacles for the slip movement as the slip direction should be changed when it crosses the boundary. As a result of the above strength of polycrystalline materials is higher, than that of mono-crystals.

Slip and twinning processes, occurring during plastic deformation result in formation of preferred orientation of the grains.

If the stress value required for a slip is higher than cohesion strength, metal fracture occurs.

Stress-strain relations are considered in the article Tensile test and Stress-Strain Diagram.

to top