Main page

About us

Sliding Bearings Consulting

Advertising Opportunities

Command disabled: export_raw

Adhesive joints

Dr. Dmitri Kopeliovich

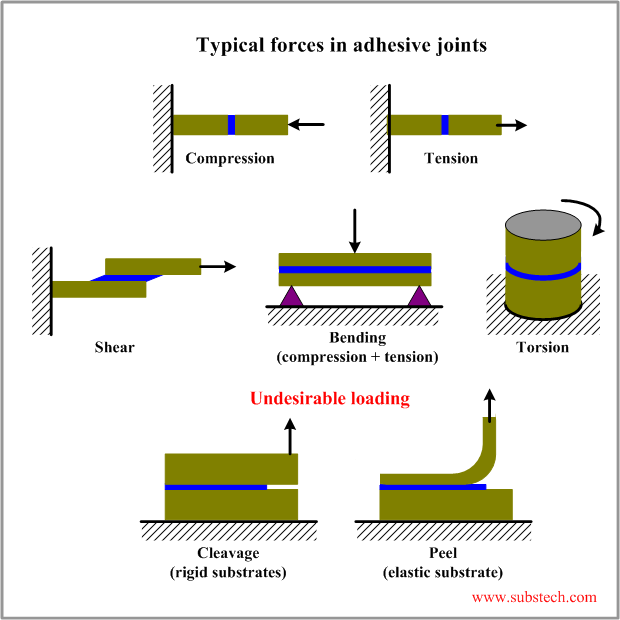

Strength of an adhesive bonding strongly depends on the direction and distribution of the stresses formed in the joint as a result of the loads applied to it.

Typical forces, which may be applied to adhesive joints are presented in the figure below.

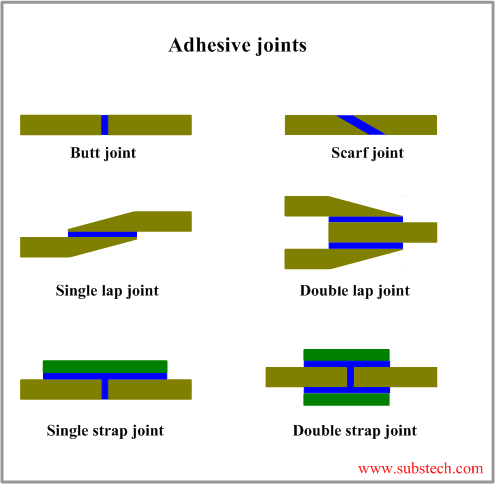

Two aderends (substrate) may be bonded by different ways shown in the picture.

Lap and strap joints provide the maximal bonding strength. Butt joint is the weakest joint type.

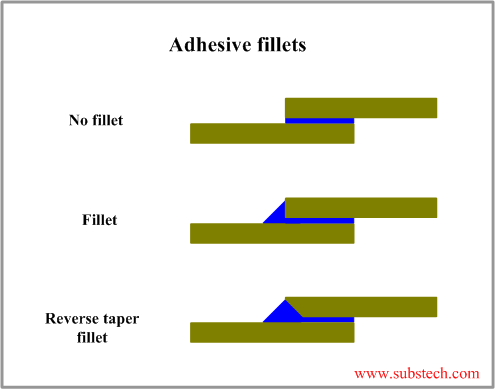

Fillet joint imparts additional strength to the adhesive joints.

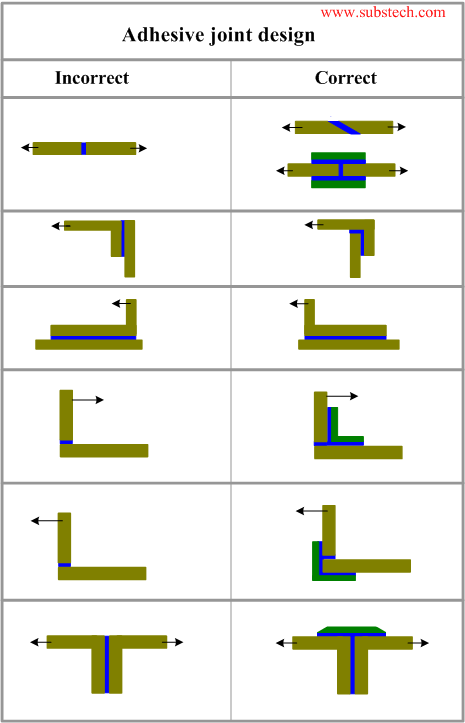

Basic rules of adhesive joint design:

- Peeling and cleavage stresses should be minimal;

- Shear stress is preferrable than tension;

- Bonding area should be as large as possible;

- Adhesive layer thickness should be minimal and uniform.

The figure below presents design of several joint types at different loading conditions.

to top

Related internal links