SubsTech’s sister website Smooth Sliding provides independent engineering consulting services that help you to solve engine bearing related issues: failures, material selection, geometry design and optimization of hydrodynamic conditions.

Smooth Sliding is an engineering consulting company run by Dr. Dmitri Kopeliovich:

- VP R&D of King Engine Bearings.

- World leading expert (32 years of experience) in design, technology and materials for Engine bearings in applications such as automotive, renewable energy, aviation, racing and others.

- Founder and owner of SubsTech (Substances & Technologies) – a leading professional website on Materials Science and Engineering.

- Author of numerous scientific and engineering publications and patents.

- Founder and owner of Smooth Sliding.

For further information and for requesting consulting services please visit our sister website Smooth Sliding.

to Metals

to Engine bearings

Polymer Coatings for Race Engine Bearings

Introduction

Most of racing engines work at very high loads, generated in the cylinders, and at high rotation speeds. Such conditions together with use of low viscosity engine oils cause substantial reduce of the minimum oil film thickness, which separate the bearing and the journal surfaces. Under such conditions, metal-to-metal contact occurs frequently. Such contact requires a bearing material with superior anti friction properties. Lack of liquid lubricant (oil) during mixed lubrication [1] may be compensated by a bearing surface consisting of a polymer matrix. Containing solid lubricants distributed in the form of fine particles, this polymer matrix can be applied as a coating to existing bearings to serve as the top layer. Such coatings may also contain particles of reinforcing phase added for greater strength and wear resistance. Similar to oil film, a polymer coating separates the metallic bearing material from the crankshaft surface.

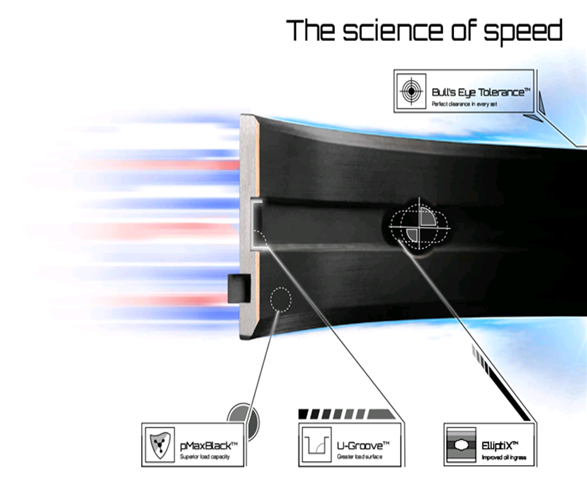

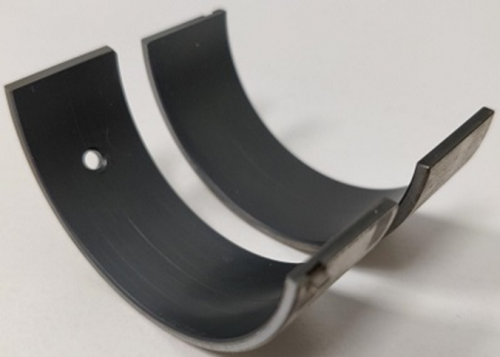

Polymer coatings K-334, K-340 and K-40, developed by King Engine Bearings (Fig.1) are composed of different types of inorganic and ceramic additives dispersed in a polymer matrix [2]. The additives have nano-dimensions. Thus, the coating material may be defined as a polymer ceramic nano-composite.

Fig.1 Polymer coated King race bearings

to top

XPC (pMax Kote™)

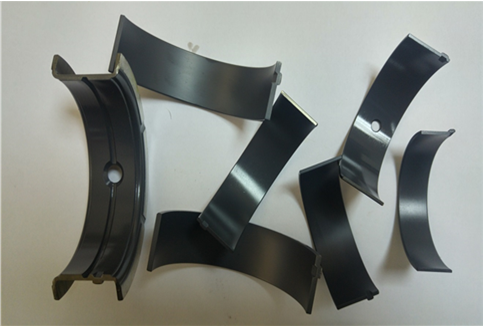

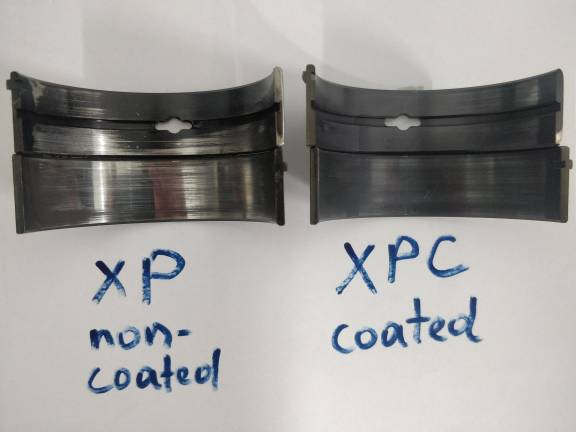

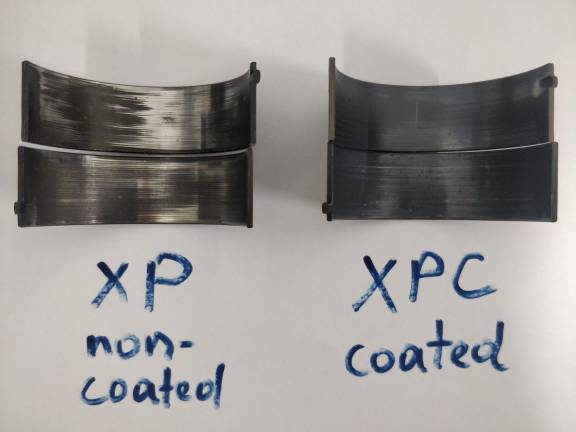

pMax Kote™ (XPC) is the King principal polymer coated race engine bearing material. Its surface is coated with the K-334 coating - wear resistant polymer developed for applying over relatively soft substrate of the tri-metal pMax Black™ (XP) high performance bearings. The coating helps to improve XP bearing wear resistance under conditions of metal-to-metal contact. It also increases resistance to cavitation erosion. In contrast to other coated bearing manufacturers and suppliers, King pMax Kote™ does not affect oil clearance. The wall thickness of these King coated bearings is equal to that of non-coated King bearings. Fig.2 depicts comparison of the basic material pMax Black™ (XP) and the coated version King pMax Kote™ (XPC).

Fig.2 Structure of pMax Black™ (XP) and pMax Kote™ (XPC) bearings

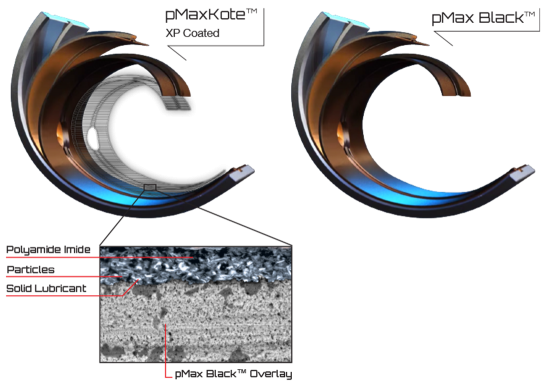

A performance comparison of polymer coated tri-metal race bearings, from four leading bearing manufacturers/suppliers; under the regime of metal-to-metal contact is presented in Fig. 3.

Fig.3 Bearings tested in King Test Rig in mixed lubrication regime at 10,150 psi for 24 hrs.

Two conclusions can be made from the tests:

- The wear rate of King pMax Kote™ (XPC) is the least of the four tested manufacturers

- The Fatigue strength (load capacity) of King pMax Kote™ (XPC) bearings is greater than that of competitive materials, which have clear fatigue cracks in the overlay

Comparative test: pMax Kote™ (XPC) vs. pMax Black™ (XP)

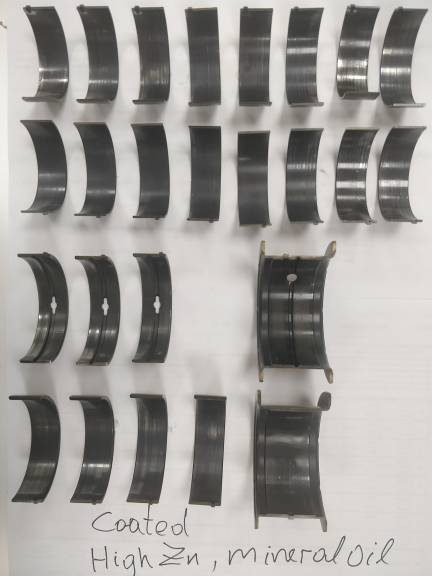

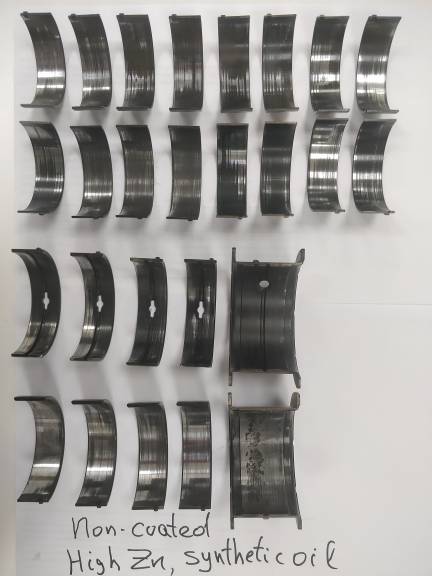

A significant positive effect of a polymer coating on the performance of King pMax bearings has been proved in the series of comparative experiments conducted in the Dynamometer of Shaver Specialities. The experiments also compared the effect of oil type (mineral and synthetic) on the bearing characteristics.

Test conditions:

Location: Shaver Specialties

Date: June 4th - 8th, 2018

Engine: 383 CI Small Block Chevy

Bearing Clearances: .0025 to .0028 inch

Speed: 1,500-3,000 RPM

Torque: 75 – 225 Ft*lb

Oils: 5W-20 Mineral and 5W-20 Synthetic

Fig.4 and 5 demonstrate evident effect of polymer coating on wear of the bearing surface under the conditions of direct friction.

Fig.4 pMax Black™ (left) vs. pMax Kote™ (right) Bearings Tested in Mineral Oil

Fig.5 pMax Black™ (left) vs. pMax Kote™ (right) Bearings Tested in Synthetic Oil

Excellent lubricating properties of the polymer coating results in much more uniform and low friction contact between the crankshaft and the bearings (Fig. 6, 7).

Fig.6 pMax Black™ (left) vs. pMax Kote™ (right) Main Bearings

Fig.7 pMax Black™ (left) vs. pMax Kote™ (right) Connecting Rod Bearings

The analyses of oil have proved the conclusions made from the visual observation.

Table: Oil Composition after Comparative Test

| Oil | Mineral oil 5W20 | Synthetic oil 5W20 | ||

| Bearings | Non-coated | Coated | Non-coated | Coated |

| Oil max. temp. , F | 286 | 292 | 300 | 283 |

|---|---|---|---|---|

| Iron, ppm | 6 | 4 | 3 | 3 |

| Lead, ppm | 16 | 11 | 23 | 4 |

| Tin, ppm | 2 | 1 | 3 | 0 |

| Copper, ppm | 9 | 4 | 2 | 2 |

| Aluminum, ppm | 2 | 1 | 1 | 0 |

| Total impurities, ppm | 35 | 21 | 32 | 9 |

| Viscosity, cSt | 9.1 | 9.1 | 9.1 | 9.1 |

Amount of metallic impurities in oil from the engines equipped with the polymer coated bearings was substantially lower than in the oil worked with non-coated bearings. The effect of coating was particularly strong in the synthetic oil where the level of metallic impurities after the test with coated bearings was as low as 9 ppm, whereas the oil worked with non-coated bearings contained 32 ppm of impurities.

to top

GPC - High Strength Polymer Coated Silver Bearings for Race Engines

Diesel racing engines and high compression ratio alcohol fuel engines (Sprint Car) produce high pressure in the cylinders. Therefore, they require bearing materials with high Fatigue strength (load capacity). Due to the increase in bearing loading, oil film thickness may be insufficient to prevent metal-to-metal contact between the bearing and journal surfaces [3]. One more challenge of high loaded engines is insufficient rigidity of their crankshafts and housings. Crankshafts bend under load. Their journal surfaces become non-parallel to the bearing surfaces. This causes local breaking of hydrodynamic lubrication and edge wear. King Engine Bearings Ltd. has developed unique bearing material GPC for modern diesel racing engine and for other high loaded applications like Sprint Car.

Bearing features:

- Special high strength steel back

- Specially developed bronze lining having extreme load capacity

- Silver anti-friction layer

- Lubricating polymer coating layer

GPC bearing combines extremely high load capacity with excellent conformability. All materials are lead-free.

One of the most important engine bearing properties is Fatigue strength (load capacity). Fatigue cracks start on the surface and then penetrate into the material. All layers of the multilayer material must have fatigue strength greater than the actual load applied to the bearing. Operation of bearing in high load racing engines is characterized with ultra-thin oil films and frequent direct contact between the bearing and the journal surfaces. The design and unique materials of the bearings allow operation under the conditions of mixed (partially hydrodynamic) lubrication.

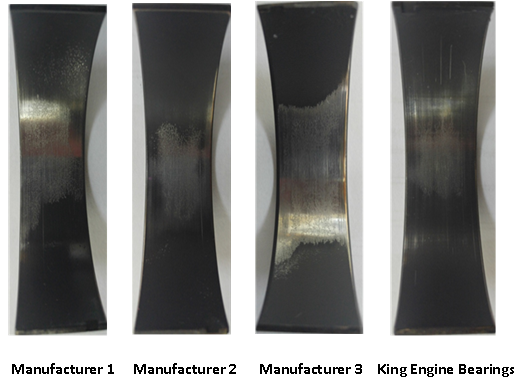

Fig.8 depicts the bearings just before application of the polymer coating. The uniform white overlay seen in the image is the silver coating. It provides the combination of high fatigue strength (up to 17,400 psi) with good ant seizure properties.

Fig.8 Silver Bearings before Polymer Coating Deposition

The silver bearings are additionally coated with King polymer coating K-340 providing excellent anti-friction properties (conformability, embedability, and seizure resistance). On the other hand, K-340 is a strong coating, offering exceptional wear resistance, toughness and fatigue strength. It was designed for applying over relatively hard substrates: bronze, aluminum alloys, Sputter bearing overlays, and King silver overlay. Hardness of the coating is about 46 HV, which is harder than most aluminum bearing alloys. The coating is able to operate under loads up to 17,400 psi (120 MPa) in diesel direct injection engines, turbocharged gasoline engines and alcohol fuel engines.

Exceptional performance of GPC bearings has been demonstrated in the supercar endurance test (Fig.9).

Fig.9 Polymer Coated Silver Bearings after Supercar Endurance Test

The bearings surface has retained the original appearance without signs of wear, fatigue or seizure.

to top

TFC - Polymer Coated Bearings for Top Fuel Applications

The conditions of bearing operation in Top Fuel engines differ considerably from those of other race types. The loads applied to the bearings are so great that hydrodynamic lubrication becomes impossible. The bearing surface contact the crankshaft continuously. The load applied to the bearing cause plastic deformation of not only the bronze lining but also the steel back. This means that the specific load is greater than the yield strength of steel. Of course, the actual loads exceed the fatigue limit of bronze and of the overlays. However, fatigue cracks do not have enough time to form due to very short duration of the race.

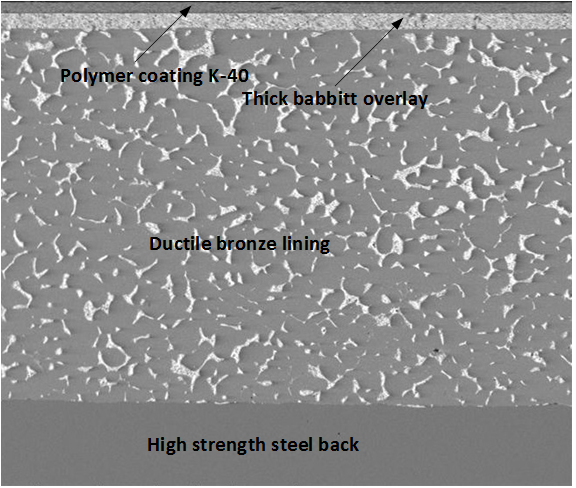

King has developed a special material TFC for the Top Fuel applications. TFC material is composed of:

- High strength steel with an increased yield strength, resisting plastic deformation of the steel back.

- Ductile bronze lining supporting high loads and plastic deformation without cracks formation.

- Thick Babbitt overlay (0.0012”) providing excellent anti-friction properties under the conditions of boundary lubrication (direct friction).

- A polymer coating K-40. It is a relatively soft coating. It is sacrificial by design, with excellent conformability and anti-friction properties. K-40 was designed especially for engines experiencing continuous metal-to-metal contact. This is characteristic of the extreme loading and conditions found in Top Fuel engines.

Fig.10 depicts a microscopic image of the material.

Fig. 10 Microstructure of the bearing material for Top Fuel applications (image from a scanning electron microscope)

The combination of lubricating properties of the two coatings with their thicknesses guarantees reliable bearing operation under the specific conditions of the Top Fuel Races (Fig.11).

Fig.11 Top Fuel Coated (TFC) bearings after a Top Fuel Race

to top

Conclusions

- King coatings are polymer ceramic nano-composites combining lubrication properties with excellent wear resistance, toughness, fatigue strength and cavitation resistance.

- pMax Kote™ (XPC) coated race bearings demonstrated superior wear resistance and fatigue strength among bearings from four leading manufacturers/suppliers

- A significant positive effect of a polymer coating K-334 on the performance of King bearings has been proved in the series of comparative experiments pMax Kote™ (XPC) vs. pMax Black™.

- King has developed unique bearing material GPC for modern diesel racing engine and for other high loaded applications like Sprint Cars. The bearings combine high strength (due to strong bronze lining and silver overlay) with very good antifriction properties provided by the polymer coating P-340.

- A material TFC for Top Fuel engine bearings having exceptional ability to work under continuous direct friction conditions has been developed. The material has a thick Babbitt overlay covered with a soft low friction polymer coating K-40.

Related internal links

References

[1] Dmitri Kopeliovich, “Lubrication regimes” SubsTech (Substances & Technologies). Retrieved from www.substech.com/dokuwiki/doku.php?id=lubrication_regimes

[2] Dmitri Kopeliovich, Polymer Coated Bearings, Engine professional, AERA., (January-March 2017), p.48-49.

[3] Dmitri Kopeliovich, “Modern Trends In Materials For High Performance Engine Bearings” SubsTech (Substances & Technologies). Retrieved from http://www.substech.com/dokuwiki/doku.php?id=modern_trends_in_materials_for_high_performance_engine_bearings

to Metals

to Engine bearings