to Metals

to Coating technologies

Vapor deposition

Dr. Dmitri Kopeliovich

There are two basic vapor deposition processes:

Physical Vapor Deposition (PVD)

Physical Vapor Deposition (PVD) is the process involving vaporization of the coating material in vacuum, transportation of the vapor to the substrate and condensation of the vapor on the substrate (part) surface.

Vaporization of the coating material stock may be made by one of the following methods:

- Evaporation

- Arc Vaporization

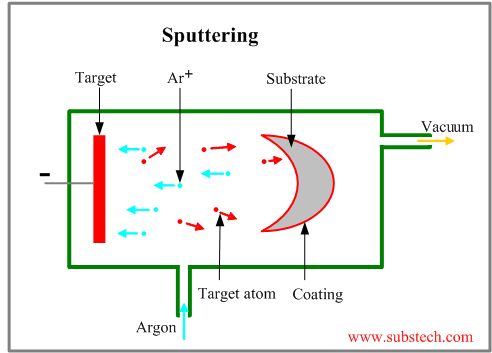

Sputtering is a Physical Vapor Deposition method, utilizing argon ions for bombarding a cathodically connected target, made of the coating material.

Atoms of the target are knocked out by the high energy ions and deposit on the substrate surface.

Sputtering process scheme is shown in the picture:

Metals, alloys, ceramics and some polymers may be deposited onto metals, ceramics and polymers by Physical Vapor Deposition method.

Applications of PVD:

- TiN, TiAlN, TiCN and CrN coating for cutting tools;

- AlSn coating on engine bearings, diamond like coating for valve trains;

- Coating for forming tools;

- Anti-stick wear resistant coating for injection molds;

- Decorative coatings of sanitary and door hardware.

Chemical Vapor Deposition (CVD)

Chemical Vapor Deposition (CVD) – the process, in which the coating is formed on the hot substrate surface placed in an atmosphere of a mixture of gases, as a result of chemical reaction or decomposition of the gases on the substrate material.

Applications of CVD:

- Integrated circuits;

- Optoelectrical devices;

- Micromachines;

- Fine powders;

- Protective coatings;

- Solar cells;

- Refractory coating for jet engine turbine blades.

Related internal links

to Metals

to Coating technologies