to Metals

to Coating technologies

Rinsing

Dr. Dmitri Kopeliovich

Rinsing is a preparation of a work part for a subsequent operation by a dilution of the chemical substances adhered to the part in the previous operation.

An improperly rinsed part may produce stains on the surface and cause an insufficient adhesion strength of the subsequent coating.

In addition, poor rinsing results in a contamination of the subsequent tanks.

Effectiveness of rinsing is measured by the parameters called Dilution Factor.

Dilution Factor (D) is the ratio of the concentration of the main chemical in the process tank to the rise of its concentation in the rinse tank as a result of the rinsing step.

Dilution Factor may also be calculated as the ratio of the rinsing tank volume Vr to the drag-in volume Vd:

D = Vr/Vd (1)

A combination of a low concentration of the main chemical substance in the rinse tank with a low rinsing water flow may be achieved by the following rinsing methods:

Countercurrent rinsing

According to the formula (1) good rinsing may be achieved by means of a large amount of water flowing at a rate exceeding the the drag-in rate by the factor D (Dilution Factor).

However the amount of rinse water may be considerably reduced in the rinsing practice called Countercurrent Rinsing.

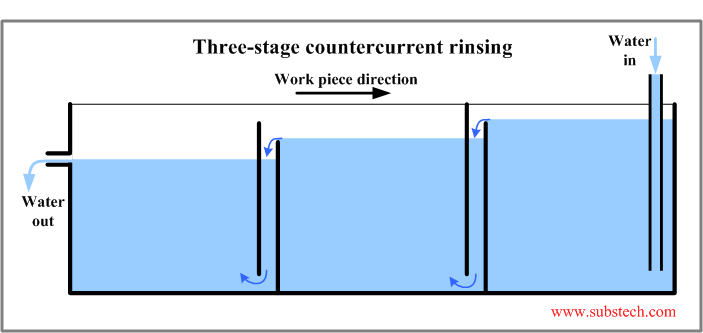

Countercurrent rinsing is the rinsing operation conducted in a sequence of rinsing tanks through which water flows in the diraction opposite to the direction of the work part.

Fresh water enters the last (cleanest) rinsing tank at its bottom, crosses the tank space and leaves the tank by overflow on the top. The water stream flows down driven by gravity to the bottom where it enters the preceding tank. The process goes and water exit the rinsing system in the first (dirtiest) tank.

Commonly countercurrent rinsing systems have a sequence of either two or three rinsing tanks (two-stage countercurrent rinsing, three-stage countercurrent rinsing).

Countercurrent rinsing allows drustical reduction of rinsing water (by 90-95%).

In a three-stage countercurrent rinsing system with the Dilution Factor D=20 the chemical concentration in the last rinse tank is:

Cr = Cd/203 = Cd/800

Where Cd/ is the concentration of the chemical in the drag-in (in the previous operation tank).

Rinsing water flow F necessary to dilute (rinse) the dag-in from the concentration Cd to the concentration Cr in a countercurrent rinsing with N stages may be calculated as follows:

F = N*Fd*(Cd/Cr)1/N

Where Fd is the drag-in flow rate.

In the example of Cd/Cr = 1000 we obtain:

F/Fd (one tank) = 1000

F/Fd (two tanks) = 63

F/Fd (three tanks) = 30

Thus three-stage countercurrent rinsing allows reduction of the rinsing water flow by the factor 33 (as compared to a simple rinsing).

to top

Static rinsing

Static rinse tank is used in order to reduce drag-out from a process tank. The work part is submerged into the static rinse tank twice: just before going to the process tank (pre-dip) and as a first rinsing step after the part came out of the process tank.

After some time the concentrations of the chemicals in the static tank stabilize at the level of 50% of those in the process tank.

Therefore static rinse tank allows on one hand to reduce drag-in enetring the countercurrent rinsing system and on the other hand to reduce the drag-out from the process tank to a half. In addition, the solution from the rinse tank may be periodically added to the process tank to compenstae water evaporated from it and to recover some of the draged-out chemicals.

to top

Agitation

Agitation (movement) of rinsing water enhances dissolution of the chemicals adhered to the work part surface. Therefore agitation increases rinsing efficiency and allows reduction of the rinsing time.

The following agiation techiques are used:

- Air agitation. This is the most widely used agitation method. Air is blown into the rinsing water through distribution pipes located at the tank bottom. The air bubbles float creating turbulent stirring of water. The maximal agitation effect is achieved by uniformly distributed bubbles pumped into the tank at high flow rate. Low pressure blowers equipped with air filters are used for air agiation. Compressed air commonly contains oil therefore it can not be used for agitation.

- Forced water agitation. Rinsing water may be driven by a water pump producing streams flowing along the work part surface and enhancing the rinsing process.

- Mechanical agitation. This technique utilizes mechanical sttirrers (propellers) driven by an electric or air motors.

- Ultrasonic agitation. This type of agitation is used for rinsing work parts having regions hardly accessible in other agitation methods.

Spray rinsing

Spray rinsing is a rinsing technique utilizing the effect of water jets spraying over the work part by nozzles installed at the tank top.

Spray rinsing may be used two configurations:

- Spray rinsing above a rinsing tank. It operates when the plating jig moves down to or/and up from the tank.

Spray rinsing over a rinsing tank results in a reduction of water consumption by 25% as compared to dip rinsing.

Spray rinsing is commonly combined with a dip rinsing.

- Spray (mist, fog) rinsing above a process tank. Sometimes spray rinse nozzles are installed over a process tank where they partially remove the solution adhered to the work parts during the jig movement up from the tank. The method allows significant reduction of drag-out. Since rinsing operation is performed over the process tank the amount of water in every rinsing cycle should not excceed the evaporation losses. In this case water is sprayed together with pressurized air forming mist/fog. The method allows to reduce water consumption to 1/4 of that in a conventional dip rinsing. The limitation of the spray rinsing over a process tank is a requirement of substantial evaporation losses which are possible only in heated baths. Only deionized water may be used in this method.

Air knives

Air knives are jets of pressurized air blowing the liquid (drag-out) adhered to the work part off when the jig is beeing withdrawn from the process tank up.

Air knives are produced by nozzles installed at the tank top.

Air knives are capable to reduce drag-out by 75%. The drag-out blown off from the work part is returned back to the tank. Use of air knives allows considerable reduction of the rinsing water consumption.

The main disadvantage of air knives is oxidation (staining) of the work part surface by the pressurized air.

to top

Reactive rinsing

Reactive rinsing utilizes the effect of neutralization of alkaline solution dragged from the Alkaline cleaning bath by the acid contained in the rinsing tank.

Commonly the Surface preparation prior to Electroplating includes Alkaline cleaning, rinsing, acid activation and rinsing after acid treatment.

If rinsing operations are performed in the same rinsing tank the alkaline drag-out is mixed with the acidic drag-out and neutralize each other.

The reactive rinsing method considerably reduces drag-in of alkaline solution into the acid process tank.

to top

Related internal links

to Metals

to Coating technologies