to Metals

to Powder metallurgy

Die pressing of metallic powders

Dr. Dmitri Kopeliovich

Die pressing (molding) is the powder compaction method involving uniaxial pressure applied to the powder placed in a die between two rigid punches.

Die (uniaxial) pressing is effectively used for mass production of simple parts (alternative method is isostatic pressing).

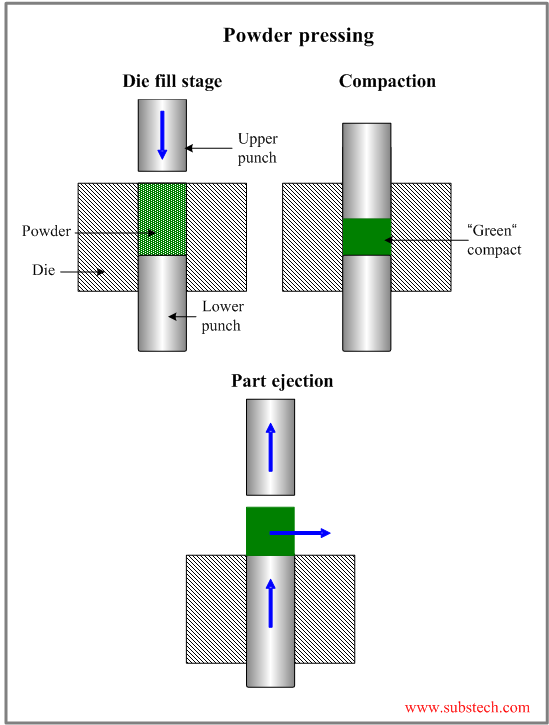

The scheme of the die pressing method is presented in the picture:

The pressing process consists of the following stages:

- Die filling.

At this stage a controlled amount of the powder is fed into the die cavity.

- Compaction.

Upper punch moves down and presses the powder with a predetermined pressure. The pressure varies between 10,000 psi to 120,000 psi (69 MPa to 830 MPa).

- “Green” compact part ejection and removal (“green” compact – unsintered powder compact) .

The pressing cycle repeats 400 to 5000 times/hour, depending on the press type, powder filling properties and the part size and geometry.

Hydraulic and mechanical presses with load up to 750 tons are used for the powder die pressing.

Die pressing, which is conducted at thr room temperature is called cold pressing.

If the pressing process is conducted at increased temperature it is called hot pressing.

Hot pressing permits obtaining better compaction, higher green compact density and higher (than in cold pressing) strength of the part.

to top