to Metals

to Foundry technologies

Die casting

Dr. Dmitri Kopeliovich

Die casting is a process, in which the molten metal is injected into the mold cavity at an increased pressure up to 30,000 psi (200 MPa).

The reusable steel mold used in the die casting process is called a die.

Die casting is a highly productive method of casting parts with low dimensions tolerance and high surface quality.

The following parts are manufactured by die casting method: automotive connecting rods, pistons, cylinder beds, electronic enclosures, toys, plumbing fittings.

The molten metal injection is carried out by a machine called die casting machine.

There are two principal die casting methods: hot chamber method and cold chamber method.

Cold chamber die casting

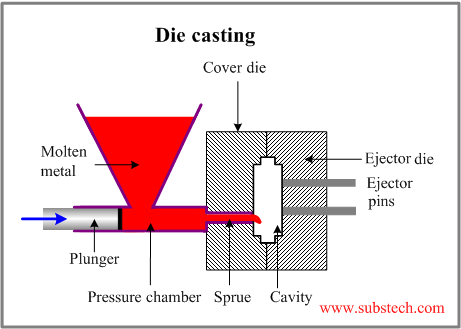

In the cold chamber die casting machines hydraulically operated plunger forces a molten metal to flow in the cold cylinder (chamber).

A principal scheme of the cold chamber die casting machine is shown in the picture:

Cold chamber process:

- When the pressure chamber is filled with a molten metal the plunger starts traveling forward and builds up a pressure forcing the metal to flow through the sprue to the die cavity.

- After the metal has solidified the plunger returns to its initial position allowing a new portion of the molten metal to fill the pressure chamber.

- The die then opens and the ejector pins removes the casting from the die.

- The casting cycle now may be repeated.

Cold chamber method is mainly used for casting Aluminum alloys, Magnesium alloys, Copper alloys and zinc alloys (including zinc-aluminum alloys).

to top

Hot chamber die casting

In the hot chamber die casting machines the pressure chamber (cylinder) and the plunger are submerged in the molten metal in the pot (crucible).

Hot chamber machines have short casting cycle (about 1 sec.). They are capable to cast thin wall casting with good filling the cavity under precise temperature control of the molten metal.

Hot chamber process may be used for casting low melting metals, which are chemically inert to the material of the plunger and other parts of the casting machine: zinc alloys (except zinc alloys containing more than 10% of aluminum), tin alloys and Magnesium alloys.

Maintenance of hot chamber machines is more expensive as compared to the cold chamber process.

Hot chamber process:

- The plunger goes up allowing the melt to fill the cylinder space. The die is closed at this stage.

- The plunger goes down forcing the melt to flow through the gooseneck into the die cavity.

- After the die has been filled with the melt the plunger is held under a pressure until the Solidification is completed.

- The die opens. The casting stays in the die part equipped with ejectors.

- The plunger goes up and the melt residuals return through the gooseneck back to the pot.

- The ejectors push the casting out of the die.

Design aspects of die casting

- Since the metallic mold of a die casting expands when it is filled with a molten metal and then both the casting and the mold shrinks during cooling the shrinkage allowances taken in the die mold design are smaller than those in the Sand casting.

- Parts of 0.05 lb (20 g) to 75 lb (34 kg) may be cast.

- The section thickness of permanent mold casting may vary in the range 0.02” - 0.5” (0.5-12 mm).

- The dimensional tolerances are 0.01-0.03” (0.25-0.75 mm) depending on the casting section thickness.

- Allowances of 0.004-0.01” (0.1-0.25 mm) are taken for the dimensions crossing the parting line of the mold.

- The draft angle is commonly about 1%.

- Lower (as compared to other casting methods) radii of the part corners may be achieved by die casting process.

- Changes of the section thickness should be as gradual as possible.

- The parting line should not cross critical dimensions.

- Water-cooled dies may be used for obtaining faster Solidification at a desired direction.

- The dies are fabricated from Tool and die steels. The die life is determined the ability of the material to withstand wear caused by the molten alloys and Fatigue caused by multiple heating and expansion.

- The cores are made of refractory ceramic materials. Sand based cores are not applicable due to their insufficient strength under pressure applied in die casting.

Advantages and disadvantages of die casting

Advantages of die casting:

- High productivity.

- Good dimensional accuracy.

- Good surface finish: 2-100 µinch (0.5-2.5 µm) Ra.

- Thin wall parts may be cast.

- Very economical process at high volume production.

- Fine Grain structure and good mechanical properties are achieved.

- Intricate shapes may be cast.

- Small size parts may be produced.

Disadvantages of die casting:

- Not applicable for high melting point metals and alloys (eg. steels)

- Large parts can not be cast.

- High die cost.

- Too long lead time.

- Some gases my be entrapped in form of porosity.

Related internal links

to Metals

to Foundry technologies